What is a Window Making Machine and How Does It Work?

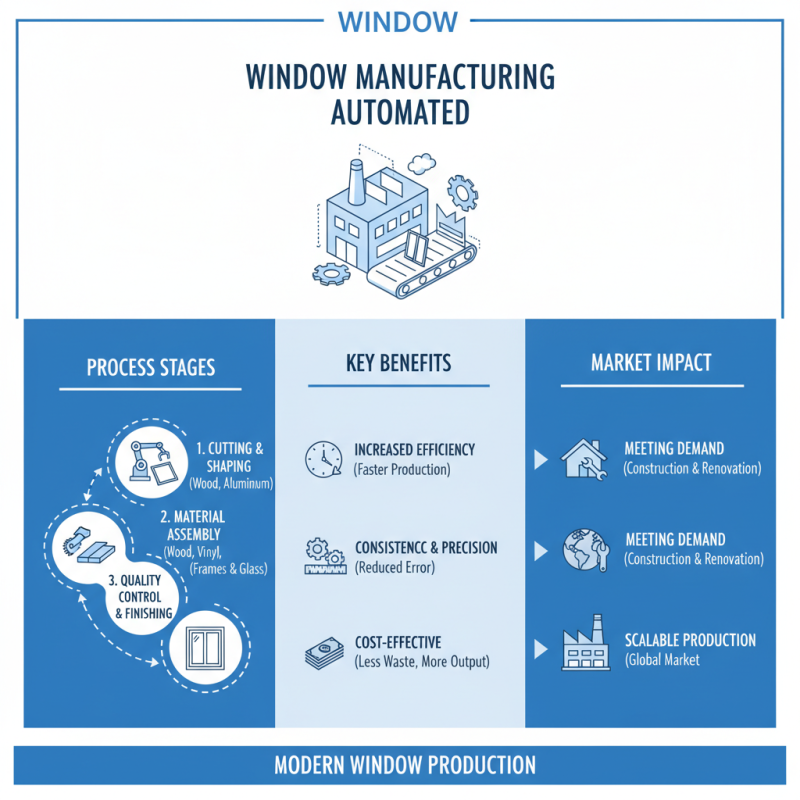

A Window Making Machine is a vital tool in the manufacturing industry. It automates the intricate process of window production, ensuring precision and efficiency. These machines are designed to cut, shape, and assemble different window materials like wood, PVC, and aluminum.

Understanding how a Window Making Machine operates can help improve production lines. The machine uses advanced technology to streamline tasks that were once manual. However, the complexity of these machines can be overwhelming at times. Operators might face challenges when adjusting settings or troubleshooting issues.

Investing in a quality Window Making Machine can lead to better output and reduced waste. It is essential to evaluate and choose a machine that meets specific production needs. Even minor mistakes in the setup can affect the entire process. Therefore, continuous learning and adaptation are key to maximizing the benefits of this technology.

What is a Window Making Machine? An Overview of Its Purpose

A window making machine is designed to streamline the process of producing windows. It automates various stages, increasing efficiency and consistency. These machines can cut, shape, and assemble different materials like wood, vinyl, or aluminum. The purpose is to meet the growing demand for windows in construction and renovation projects.

The machine typically includes a range of tools. These tools perform specific functions, such as cutting glass and joining frames. Operators must closely monitor settings for quality control. It involves a significant amount of technical knowledge. Mistakes can lead to wasted materials and increased costs. This highlights the importance of training in operating such machines.

Window making machines also evolve over time. New technologies aim to improve energy efficiency and design flexibility. However, some machines can be complex and difficult to operate. Operators may encounter learning curves. Tests and adjustments are often necessary to achieve desired results. Over time, operators learn to balance speed with accuracy, raising questions about production practices.

Key Components of a Window Making Machine in Modern Manufacturing

A window making machine is essential in modern manufacturing processes. It automates the construction of various types of windows, enhancing both efficiency and precision. The machine consists of several key components that work together seamlessly.

One primary component is the cutting unit. This unit precisely cuts materials, such as glass and frame profiles, to the required dimensions. It often uses advanced technology to minimize waste. Then, there’s the assembly station. Here, the components come together. Automated arms align and fit each piece, ensuring a tight seal. This stage is critical in maintaining the window's durability.

Another important aspect is the quality control system. This system inspects the windows for defects. It checks for any inconsistencies that could affect performance. Despite technological advancements, humans still play a role in monitoring. The machine's efficiency is impressive, but occasional errors still occur. Sometimes, components may not align perfectly. This calls for a reflection on the balance between automation and manual oversight.

What is a Window Making Machine and How Does It Work? - Key Components of a Window Making Machine in Modern Manufacturing

| Component | Description | Function |

|---|---|---|

| Cutting Unit | A device that cuts raw materials to specified dimensions. | Ensures precision and accuracy in material size for window frames. |

| Milling Machine | A machine that shapes the edges of materials. | Creates grooves and profiles for better fit and aesthetics. |

| Assembly Station | Area where components are joined together. | Facilitates the final assembly of window units. |

| Sealing Machine | Applies seals and gaskets to ensure insulation. | Improves energy efficiency and weather resistance. |

| Quality Control Unit | System for inspecting finished products. | Ensures products meet industry standards and specifications. |

The Working Principle of Window Making Machines Explained in Steps

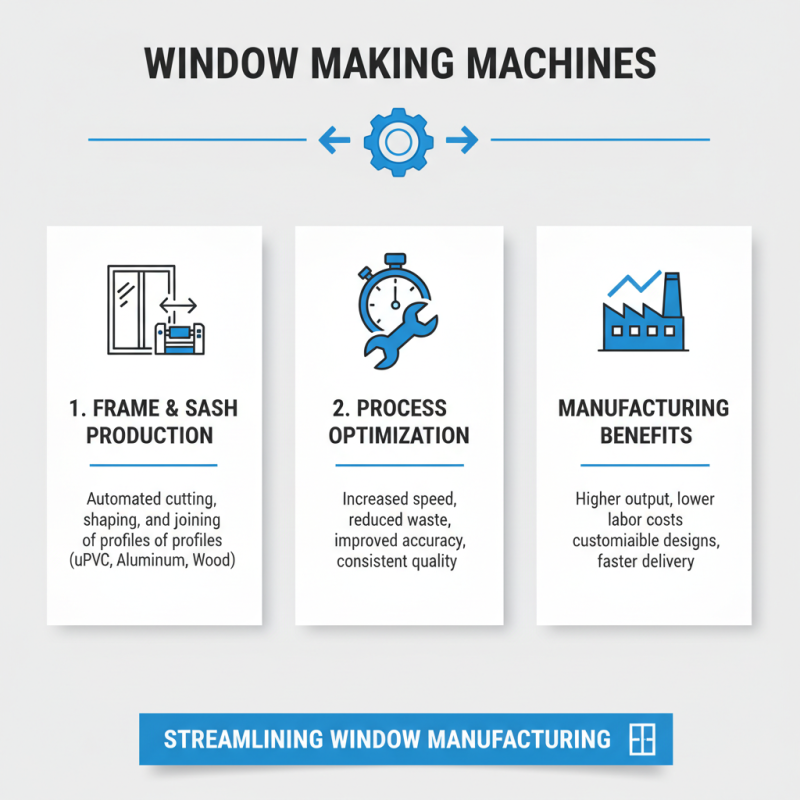

Window making machines are essential in the manufacturing industry. They streamline the process of creating window frames and sashes. Understanding how these machines work helps in optimizing production.

The working principle is quite straightforward. Initially, raw materials like aluminum or wood are fed into the machine. These materials undergo cutting, shaping, and assembling. The machine uses precision tools to ensure accuracy. Each step is crucial for quality. This precision leads to minimal waste. Operators monitor the process carefully. Sometimes, they notice minor errors. These could affect the final product. Reflection and adjustment are key to improvement.

After assembly, the windows go through quality checks. This step identifies any defects. Machines can malfunction, causing delays. It’s a learning curve for operators. They must adapt and keep refining their skills. Despite challenges, the efficiency gained from window making machines is significant. It transforms raw materials into high-quality windows.

Industry Standards and Specifications for High-Quality Window Production

When it comes to window production, adhering to industry standards is crucial. Quality begins with the selection of raw materials. High-grade materials enhance durability and aesthetics. Fabricators must follow strict specifications to ensure performance. Non-compliance can lead to issues like air leaks or poor insulation.

Window making machines are designed to meet these high standards. These machines include automated cutting and assembling features. Precision is vital for creating windows that meet energy efficiency requirements. Regular maintenance of machinery is necessary. Neglecting this can result in production errors or defects.

Tip: Always conduct regular quality checks. This ensures that each window meets performance benchmarks. Also, invest in training for operators. Well-trained staff can recognize potential issues early on. Attention to detail during production cannot be overstated. It's essential for maintaining standards and customer satisfaction.

High-Quality Window Production Analysis

This chart illustrates the cost per square meter of different window materials used in the production process. Understanding these costs is crucial for manufacturers aiming to meet industry standards for quality and efficiency.

Recent Advances in Window Making Technology and Their Impact on Efficiency

The window making industry has seen significant technological advancements in recent years. One key development is automation, which boosts production speed. According to a 2022 industry report, automated systems can increase output by up to 30%. This surge in efficiency reshapes manufacturing processes, allowing companies to meet growing demand.

Moreover, advancements in materials have improved energy efficiency. New composite materials are now prevalent. They provide better insulation, reducing heating and cooling costs. Data shows that using these modern materials can save up to 15% on energy bills. However, many manufacturers still rely on outdated materials. This reliance can hinder overall efficiency and sustainability.

Despite the progress, challenges remain. Not all plants have adopted the latest technology. Many struggle with high initial costs and inadequate training for staff. Additionally, maintenance of advanced systems can be complex, leading to unexpected downtimes. This creates a gap in potential output and actual production rates. The industry must address these issues to fully realize the benefits of recent advancements.

Related Posts

-

Evaluating Different Types of Window Manufacturing Equipment for Optimal Production Efficiency

-

Excellence in Quality Chinese Window Manufacturing Machines for Global Markets

-

The Future of Energy Efficient Windows with Advanced Window Making Machine Technology

-

Navigating Tariff Challenges with Leading Aluminium Door Machine Innovations from China

-

The Definitive Ultimate Guide to Choosing the Best Thermal Break Machine for Your Needs

-

Global Buyers Discover High-Quality Chinese Aluminum Window Machinery: A New Era of Manufacturing Excellence