Exploring Unique Features and Applications of Top Aluminium Machinery for Global Buyers

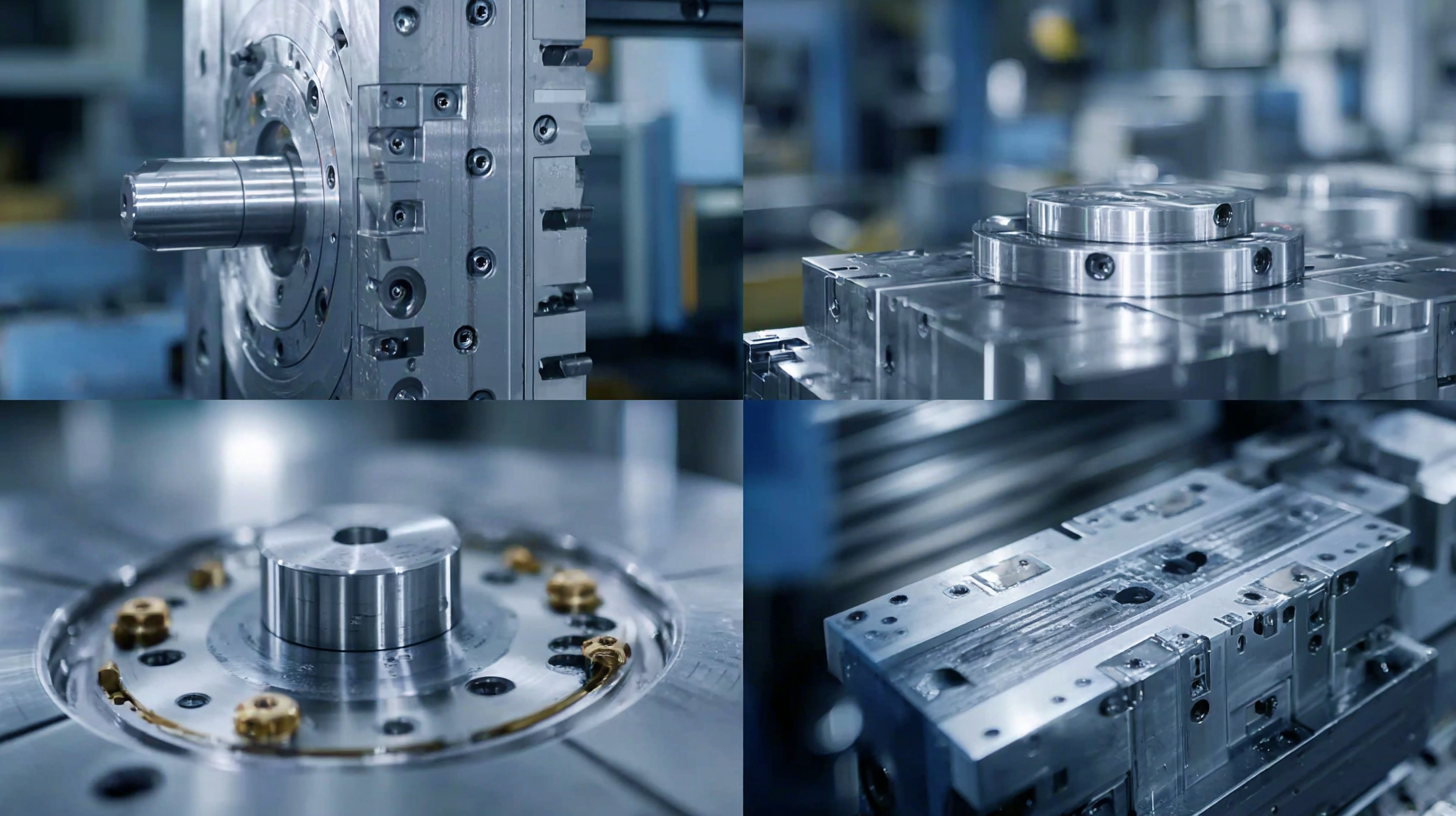

In today's rapidly evolving manufacturing landscape, Aluminium Machinery has emerged as a cornerstone for production efficiency and innovation. With their versatile capabilities, these machines cater to a wide variety of applications, from fabrication to finishing, highlighting their importance across multiple industries.

This blog will delve into the unique features of different types of aluminium machinery, exploring how each variant is tailored to meet specific production needs. By understanding the intricate design and operation of these machines, global buyers can make informed decisions that enhance productivity and quality in their manufacturing processes. We will also provide insights on how to effectively select and implement aluminium machinery in your production line, ensuring you maximize both performance and return on investment.

Whether you are a seasoned manufacturer or a newcomer to the aluminium sector, this comprehensive exploration will equip you with the knowledge you need to navigate the market successfully.

Innovative Aluminium Machinery: Key Features Revolutionizing Manufacturing in 2025

The aluminium machinery sector is poised for groundbreaking advancements in 2025, driven by the increasing demand for lightweight materials in various industries. As outlined in a report by Markets and Markets, the global aluminium processing market is projected to reach $178.1 billion by 2026, growing at a CAGR of 6.2% from 2021. This growth is largely attributed to the improved efficiency and automation achieved through innovative machinery. New technologies such as AI-driven predictive maintenance systems and smart manufacturing processes are enhancing productivity while minimizing waste.

Key features of the latest aluminium machinery include enhanced energy efficiency and advanced robotics integration. According to a study published by McKinsey, companies embracing these innovations can reduce energy consumption by up to 30%, significantly lowering operational costs and environmental impact. Additionally, the use of IoT (Internet of Things) in aluminium manufacturing provides real-time data analytics that optimize production workflows, leading to improved quality control and reduced downtime. These features not only revolutionize manufacturing processes but also position global buyers to stay competitive in an increasingly sustainable market.

Unveiling the Latest Technologies in Aluminium Fabrication Machines for Global Markets

The aluminum fabrication industry is witnessing a significant transformation fueled by the latest technologies in machinery. Advanced welding techniques, particularly laser welding, are at the forefront, reshaping the landscape for global manufacturers. The market for laser welding equipment is evolving rapidly, driven by the demand for precision and efficiency in aluminum fabrications. Various laser technologies, including fiber, solid-state, and CO2 lasers, provide manufacturers with versatile options tailored to specific applications. This range of technology not only enhances productivity but also strengthens the overall quality and longevity of aluminum products.

As the industry adapts to the challenges posed by economic fluctuations and the ongoing impact of COVID-19, the implementation of innovative machinery is more crucial than ever. The recent developments in aluminum industry policies, such as the "High-Quality Development Implementation Plan for the Aluminum Industry (2025-2027)," signal a commitment to elevating standards and practices. Furthermore, global trends towards sustainable solutions have accelerated the adoption of lightweight materials in automotive and aerospace sectors, where aluminum plays a pivotal role. Notably, with projected growth in aluminum-related markets, companies are prioritizing the integration of cutting-edge technologies to remain competitive and responsive to evolving market demands.

Aluminium Machinery Global Applications and Technologies

Practical Applications of Advanced Aluminium Machinery in Diverse Industries

The practical applications of advanced aluminium machinery span a multitude of industries, enhancing both efficiency and product quality. For instance, in the aerospace sector, advanced aluminium extrusion processes enable manufacturers to produce lightweight, high-strength components that improve fuel efficiency. According to the International Aluminium Institute, the global demand for aluminium in aviation is projected to reach 3 million tonnes by 2025, underscoring its significance in this high-stakes industry.

In the automotive industry, aluminium die-casting machinery is revolutionizing vehicle design. The lightweight nature of aluminium contributes to reduced emissions and improved fuel economy. A report by Grand View Research indicates that the aluminium die-casting market is expected to achieve a compound annual growth rate (CAGR) of 7.5% from 2021 to 2028. This surge is driven by the increasing adoption of aluminium components in electric vehicles, where weight reduction is crucial for enhancing battery performance.

Furthermore, the construction industry benefits from advanced aluminium machinery techniques, allowing for the efficient production of durable and aesthetically pleasing architectural elements. With global construction spending projected to exceed $15 trillion by 2030, the role of aluminium as a sustainable and versatile building material is more critical than ever. The integration of sophisticated aluminium machinery not only supports current industry demands but also paves the way for innovative applications in future projects across various sectors.

Future Trends: Eco-Friendly Aluminium Machinery Solutions for Sustainable Production

The future of aluminium machinery is significantly shaped by the increasing demand for eco-friendly solutions that promote sustainable production practices. As industries pivot towards greener methodologies, the aluminium sector has seen a surge in innovations tailored to reduce environmental impact. This transition is underscored by the growing Global Recycled Aluminium Market, which is projected to reach USD 148.10 billion by 2034. The demand for recycled aluminium not only conserves natural resources but also minimizes waste, marking a pivotal shift in how aluminium is sourced and utilized in manufacturing processes.

In addition to recycling efforts, advancements in aluminium technology, such as aluminium-ion batteries, are paving the way for sustainable energy storage solutions. These innovative systems are essential for enhancing energy efficiency and reducing carbon footprints across various sectors. As manufacturers embrace these cutting-edge technologies, the focus on sustainability will not only drive growth but also establish new standards for environmentally responsible production. With such trends on the horizon, the aluminium industry is poised for a transformative future that aligns economic growth with ecological responsibility.

Exploring Unique Features and Applications of Top Aluminium Machinery for Global Buyers - Future Trends: Eco-Friendly Aluminium Machinery Solutions for Sustainable Production

| Feature | Description | Application | Sustainability Impact |

|---|---|---|---|

| Energy Efficiency | Minimizes energy consumption during the production process. | Industrial production of aluminum components. | Reduces carbon footprint significantly. |

| Recycling Capability | Designed for efficient processing of recycled aluminum. | Manufacturing new aluminum products using recycled materials. | Promotes circular economy practices. |

| Modular Design | Flexible machinery that can be scaled and adapted for various tasks. | Used in small to medium-sized production facilities. | Supports resource optimization and waste reduction. |

| Automation Features | Advanced technology for reducing manual labor. | High-volume manufacturing environments. | Increases efficiency while lowering energy usage. |

| Precision Engineering | High accuracy in cutting and shaping processes. | Aerospace and automotive industries. | Improves product quality, reducing waste and rework. |

How to Select the Right Aluminium Machinery for Your Business Needs in 2025

In the rapidly evolving landscape of aluminium machinery, selecting the right equipment for your business in 2025 is crucial for maximizing efficiency and output. As the demand for lightweight materials grows, particularly in sectors such as automotive manufacturing and lithium battery production, key considerations must be taken into account. Factors such as production capacity, technological advancements, compatibility with existing systems, and after-sales support are critical in making an informed choice.

Recent market analyses indicate a robust demand for aluminium components, especially with projections indicating a compound annual growth rate exceeding 5.9% from 2025 to 2034. This surge is driven largely by the automotive industry's shift towards lightweight materials and the expanding market for aluminium-plastic film, crucial for battery applications. Buyers need to stay informed of industry trends, including innovations in aluminium processing techniques and the latest machinery offering enhanced precision and productivity. Engaging with credible suppliers and attending leading industry exhibitions can provide valuable insights, enabling businesses to make strategic investments that align with future market demands.