Finding Top Suppliers for Aluminium Windows Manufacturing Machines a Comprehensive Guide

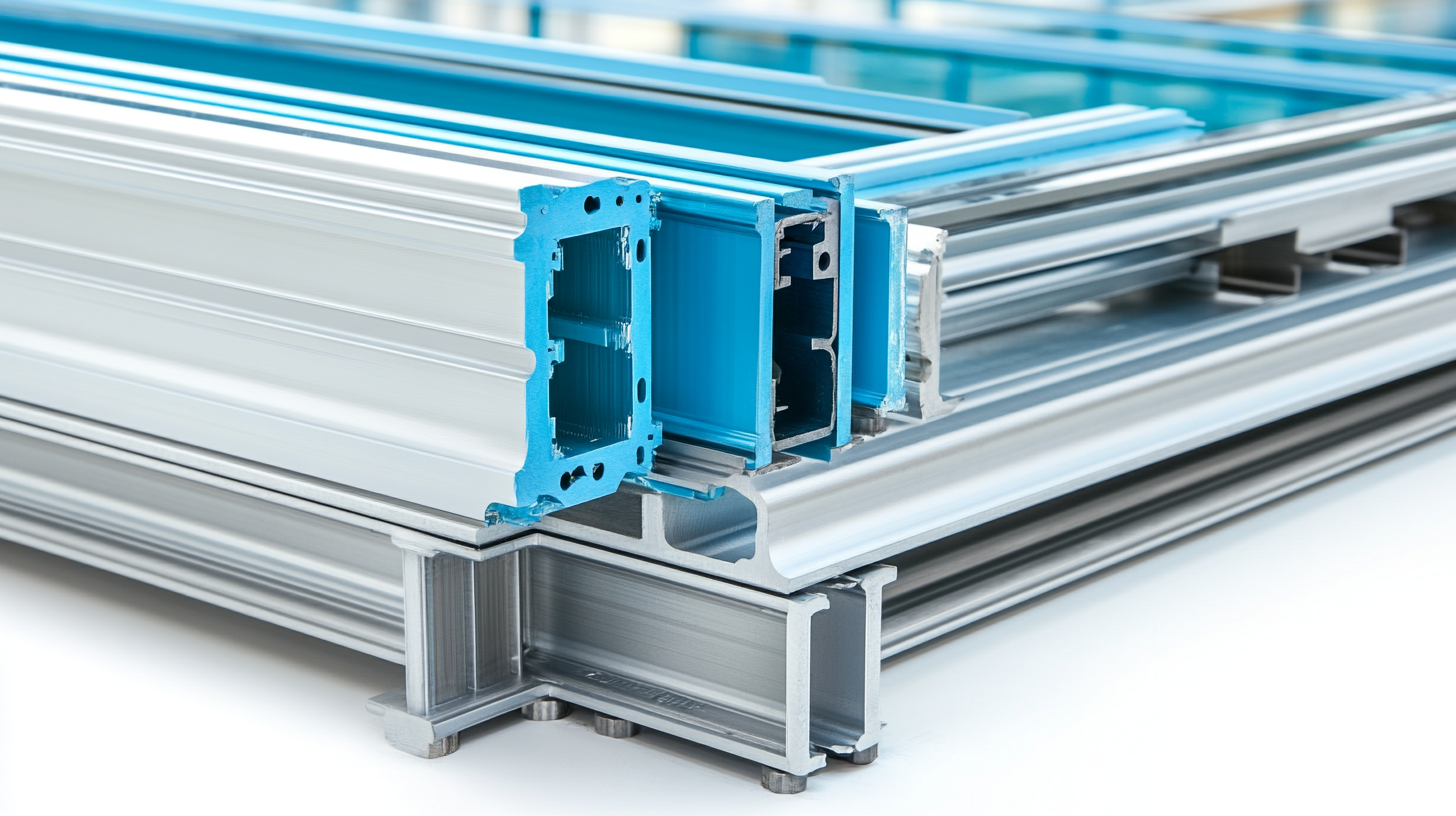

The aluminium window market has witnessed significant growth in recent years, driven by the increasing demand for energy-efficient and sustainable building solutions. According to a report by MarketsandMarkets, the global aluminium window market is expected to reach USD 98.4 billion by 2025, growing at a CAGR of 5.8% from 2020 to 2025. This surge in demand not only highlights the importance of high-quality aluminium products but also emphasizes the necessity for effective manufacturing processes. To meet this rising demand, manufacturers must invest in advanced Aluminium Windows Manufacturing Machines that enhance productivity and quality.

Finding top suppliers for aluminium windows manufacturing machines is crucial for businesses aiming to stay competitive in this dynamic landscape. These machines are not merely tools; they are pivotal in streamlining production, reducing costs, and ensuring product consistency. As the industry evolves, it is vital for manufacturers to understand the specifications and capabilities of different machines available in the market. This guide aims to provide a comprehensive overview of the essential factors to consider when sourcing these machines, ensuring that manufacturers can make informed decisions that will drive their success in the burgeoning aluminium window sector.

Understanding the Importance of Choosing the Right Supplier for Aluminium Windows Manufacturing Machines

Choosing the right supplier for aluminium windows manufacturing machines is crucial for businesses looking to thrive in a competitive market. According to a report from Research and Markets, the global aluminium windows market is projected to grow at a CAGR of 5.5% from 2021 to 2026. This growth accentuates the importance of aligning with suppliers who not only provide high-quality machinery but also incorporate the latest technology and safety standards. When selecting a supplier, it is essential to evaluate their reputation and track record in the industry. A study by Statista highlights that approximately 60% of manufacturers consider a supplier's performance history as a decisive factor in their purchasing decisions. Additionally, suppliers who offer comprehensive after-sales support can significantly enhance production efficiency, reducing downtime and maintenance costs. The effectiveness of the machinery is often directly linked to the level of service provided, making this aspect a priority for any manufacturing entity. Investing time in finding the right supplier can lead to long-term benefits, including cost savings and improved product quality. In fact, a survey by the Manufacturing Institute found that companies working with reputed suppliers experienced a 15% boost in overall productivity. Therefore, understanding the implications of supplier choice is not merely an operational decision; it can fundamentally influence the success and sustainability of aluminium windows manufacturing in today's dynamic market environment.

Key Factors to Consider When Evaluating Aluminium Windows Manufacturing Machines Suppliers

When it comes to finding the right suppliers for aluminium windows manufacturing machines, a thorough evaluation process is crucial. One of the key factors to consider is the supplier's reputation in the industry. Researching their history and customer feedback can provide insights into their reliability and the quality of their machines. Trusted suppliers often have established relationships with clients and can showcase successful case studies to substantiate their credibility.

Another important aspect to evaluate is the technological capabilities of the machines offered. Look for suppliers who utilize the latest advancements in manufacturing technology. This not only enhances productivity but also ensures superior quality in the finished products. Inquire about the specifications, features, and customizability of the machines to determine if they align with your specific production needs.

Additionally, consider the level of customer support provided by the supplier. A reputable supplier should offer comprehensive training, responsive maintenance services, and readily available spare parts. This support is vital for minimizing downtime and ensuring that your manufacturing process runs smoothly. Establishing a good relationship with a supplier who prioritizes customer care can lead to a long-term partnership that benefits your business.

Researching Market Trends and Supplier Reputation in the Aluminium Manufacturing Industry

When seeking top suppliers for aluminium windows manufacturing machines, it's crucial to first delve into market trends and the reputation of suppliers within the aluminium manufacturing industry. Understanding current market dynamics can provide valuable insights into which suppliers are leading the way in innovation and reliability. One should closely monitor industry reports and trade publications that highlight emerging technologies and shifts in consumer preferences, as these factors significantly influence supplier performance and product offerings.

Moreover, supplier reputation plays a pivotal role in the decision-making process. Conducting thorough research on potential suppliers involves examining customer reviews, case studies, and testimonials. Engaging with industry forums and networking events can also yield personal experiences and recommendations from peers who have already navigated this landscape. Reliable suppliers often participate actively in industry exhibitions, showcasing their latest machinery and technology, which further solidifies their standing in the market.

By combining an understanding of market trends with careful evaluation of supplier reputation, manufacturers can strategically identify the best partners for their aluminium windows manufacturing needs. This comprehensive approach not only ensures that manufacturers have access to top-quality machinery but also fosters long-term relationships with suppliers who are agile and responsive to the industry's evolving demands.

Comparing Prices and Services Offered by Different Aluminium Windows Machine Suppliers

When embarking on the journey to source aluminium windows manufacturing machines, it’s crucial to compare prices and services offered by various suppliers to ensure you choose the best option for your business. The market is filled with a multitude of suppliers, each offering their own unique set of features and pricing structures. By doing a thorough comparison, you can identify which providers not only meet your budget but also align with your operational requirements and quality standards.

One effective approach is to create a spreadsheet where you list potential suppliers alongside their offerings. Detail the specifications of the machines, warranty information, and any after-sales services they provide. This allows for a side-by-side evaluation of key factors that influence both cost and performance. It's also worthwhile to inquire about bulk purchasing discounts or package deals that could provide better value.

Moreover, consider the long-term support and training that suppliers offer. Some might have a higher initial cost but provide comprehensive service packages, including installation and maintenance, which can reduce downtime and enhance productivity in the long run. Engaging with customer reviews and feedback can also offer insights into the reliability and efficiency of different suppliers' machines, helping you make a more informed decision that benefits your manufacturing process.

Building Long-Term Relationships with Aluminium Windows Manufacturing Machine Providers

Building lasting partnerships with aluminium windows manufacturing machine providers is crucial for any business looking to thrive in this industry. The foundation of such relationships is built on mutual trust and clear communication. To successfully engage with suppliers, it is essential to understand their capabilities, production processes, and how they align with your specific needs. Regular meetings and transparent discussions about expectations can pave the way for a strong partnership.

Another key aspect is the consideration of suppliers' reliability and responsiveness. A supplier that consistently meets deadlines and addresses concerns promptly fosters a sense of confidence and security. It’s beneficial to assess their track record through references or case studies. This provides insights into their strengths and weaknesses, enabling you to make informed decisions when selecting the right partner for your aluminium window manufacturing needs.

Furthermore, investing in a collaborative approach can enhance these relationships. Sharing feedback and insights about the machines and how they perform in your operations can help suppliers improve their products. This collaborative spirit not only optimizes production efficiency but also encourages innovation on both sides. In a fast-evolving market, staying aligned with a dedicated supplier can significantly impact your competitiveness and success in aluminium windows manufacturing.