7 Simple Tips to Choose the Most Effective Best Aluminium Door Machine

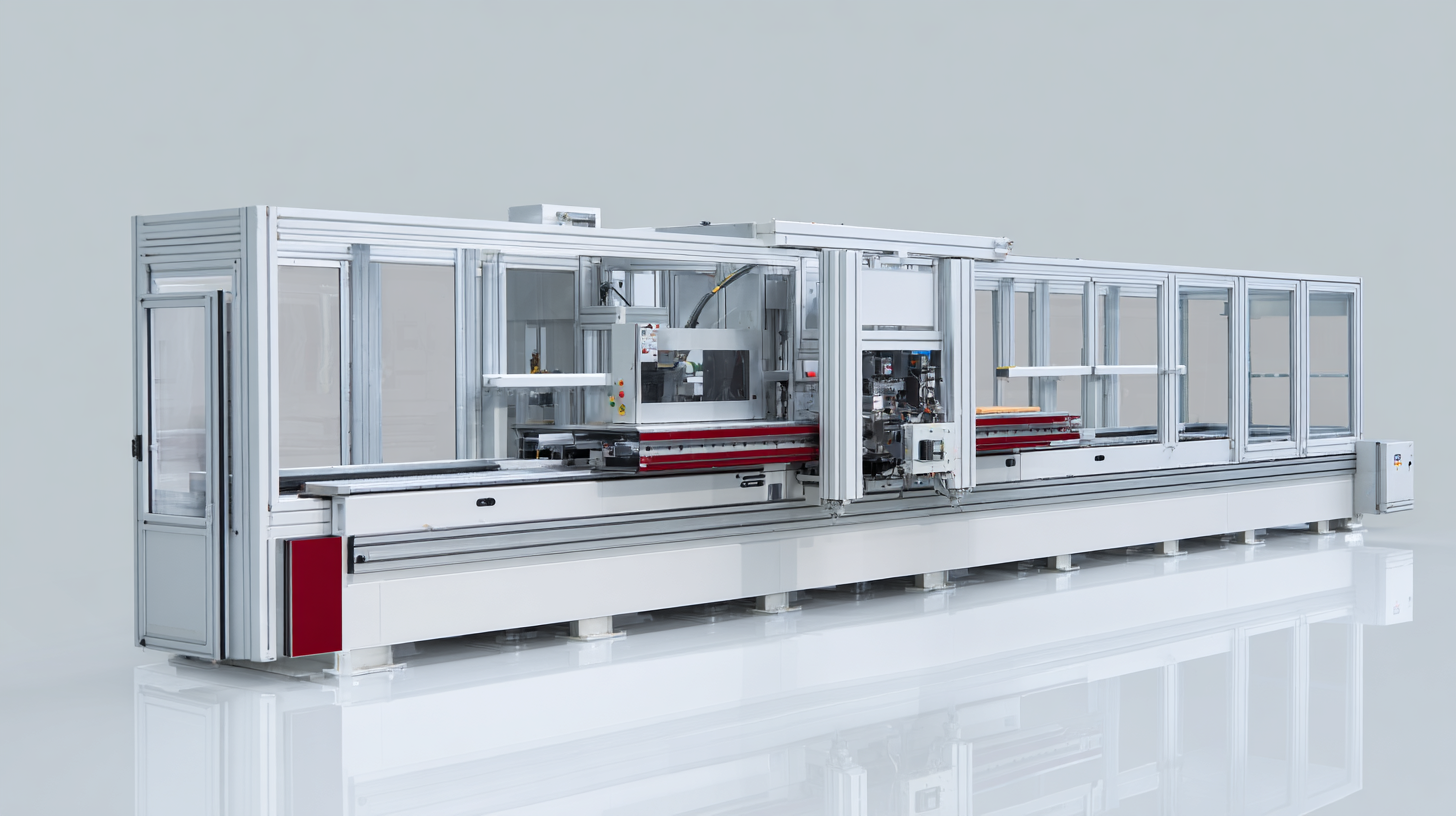

In today's fast-paced construction and manufacturing environments, the efficiency and reliability of your equipment can make a significant difference in productivity and outcome quality. Among the tools that play a crucial role in door manufacturing, the Aluminium Door Machine stands out due to its versatility and precision. Selecting the right machine for your specific needs is essential to achieving optimal results.

This blog will explore seven simple yet effective tips to guide you in choosing the most suitable Aluminium Door Machine for your business. By examining industry case studies and practical "how-to" advice, you'll gain valuable insights into what to consider when investing in this vital equipment, ensuring that you enhance your production process while maintaining the high standards of quality expected in today's competitive market.

Understanding the Key Features of Aluminium Door Machines for Optimal Performance

When selecting the most effective aluminium door machine, understanding the key features that contribute to optimal performance is crucial. A recent industry report by Market Research Future suggests that the global aluminium door machinery market is expected to grow at a CAGR of approximately 4.5% through 2027, highlighting the increasing demand for efficient and durable machinery. The right machine should prioritize precision in cutting and assembling, as these factors directly affect the quality of the final product.

One of the essential tips when choosing an aluminium door machine is to consider its automation capabilities. Machines that incorporate automated processes not only speed up production but also reduce the likelihood of human error. According to a study by Technavio, automation in manufacturing processes can enhance productivity by up to 30%. Additionally, pay attention to the machine's compatibility with various aluminium profiles, ensuring versatility in your operations.

Another vital feature to evaluate is the ease of maintenance. A machine that requires frequent repairs can significantly impact production timelines and costs. Reports indicate that businesses lose up to 20% of their output due to machine downtimes. Selecting machines designed for easy access to components and user-friendly interfaces will ultimately lead to smoother operations and better return on investment.

Comparing Different Types of Aluminium Door Machines: Pros and Cons

When choosing an aluminium door machine, understanding the pros and cons of different types is essential for making an informed decision. There are primarily two categories to consider: manual and automatic machines. According to a report by Freedonia Group, the demand for automatic machines is projected to grow by 4.5% annually due to their enhanced efficiency and ease of use. Automatic machines are especially advantageous for large-scale production, as they significantly reduce labor costs and potential mistakes during the manufacturing process.

On the other hand, manual machines are often favored by smaller operations or DIY enthusiasts for their affordability and ease of maintenance. They allow for greater control over the manufacturing process, which can result in higher craftsmanship quality, especially in custom projects. However, reliance on manual processes can limit production speed, making them less suitable for high-volume demands. A study from Technavio suggests that while manual machines may appeal for their lower upfront costs, the long-term productivity advantages of automatic machines make them a worthwhile investment for many businesses looking to optimize their operations.

Budget Considerations: Finding the Best Value for Your Aluminium Door Machine

When searching for the best value in an aluminium door machine, budget considerations should be at the forefront of your decision-making process. Understanding the features that matter most to your projects will help in allocating your budget effectively. One important tip is to assess the machine's efficiency; investing in a model that guarantees precision and speed can save you time and reduce material waste in the long run.

Another critical factor to consider is the machine’s durability and warranty. A higher initial cost might be justified if the machine offers a comprehensive warranty and is built to last. Look for models that provide robust construction, as they can withstand the rigors of daily usage without needing frequent repairs. Additionally, consider the cost of replacement parts and service; machines that are harder to maintain can lead to unexpected repair costs down the line. By focusing on these key factors, you can ensure that your investment provides the best value while meeting your aluminium door production needs.

User-Friendly Controls: Importance of Ease of Use in Choosing Your Machine

When selecting the best aluminium door machine, user-friendly controls should be a primary consideration. A machine with intuitive interfaces allows operators, regardless of their skill level, to achieve optimal results quickly. User-friendly controls often include touchscreens, clearly labeled buttons, and easy-to-navigate menus, making it easier for all team members to learn and operate the machinery effectively. This reduces the risk of errors and enhances productivity in the workplace.

Moreover, ease of use directly impacts safety in the workshop. Machines that have simpler controls minimize the likelihood of accidents, as operators can focus on their work without struggling to comprehend complicated functions. Additionally, these machines often come with comprehensive training manuals and customer support, providing further assurance that users can master the equipment without unnecessary complications. Therefore, when choosing the right aluminium door machine, prioritizing user-friendly controls can significantly enhance both efficiency and safety in your operations.

7 Simple Tips to Choose the Most Effective Best Aluminium Door Machine - User-Friendly Controls: Importance of Ease of Use in Choosing Your Machine

| Feature | Importance | User-Friendly Ratings (1-5) | Notes |

|---|---|---|---|

| Ease of Control | Essential for smooth operation | 4 | Leads to improved productivity |

| Intuitive Interface | Critical for new users | 5 | Reduces learning curve |

| Safety Features | High priority for user security | 5 | Protects users from accidents |

| Maintenance Indicators | Important for longevity | 4 | Helps in timely upkeep |

| Adjustment Controls | Essential for precise work | 4 | Affects quality of output |

| Portability | Varies by user needs | 3 | Beneficial for multiple sites |

| Support and Documentation | Important for troubleshooting | 5 | Facilitates better user experience |

Maintenance and Support: Ensuring Longevity for Your Aluminium Door Equipment

When investing in aluminium door machinery, maintenance and support are critical factors that directly impact the longevity and performance of your equipment. According to a recent report by the International Door Association, proper maintenance can extend the lifespan of door machinery by up to 30%. Regular inspections, lubrication, and timely repairs not only ensure safety but also prevent costly downtimes. Establishing a routine maintenance schedule is essential; consider allocating specific days for checks and servicing to keep the machinery in optimal condition.

In addition to scheduled maintenance, it's crucial to choose a machine that comes with robust support options. Look for manufacturers that offer comprehensive warranties and readily available customer service. A study from the National Association of Home Builders indicated that 60% of contractors rated after-sales support as a top priority when selecting machinery. This can translate into easier troubleshooting and access to spare parts, ultimately enhancing productivity.

When selecting the best aluminium door machine, here are some tips to consider: First, evaluate the energy efficiency of the machine, as energy-efficient models can significantly reduce operational costs over time. Second, conduct thorough research on the maintenance requirements of different machines and opt for one that aligns with your facility's capabilities. Finally, consider reaching out to other users for firsthand reviews regarding maintenance ease and support quality. These steps will help ensure that your investment pays off in the long run.