What is a Steering Cylinder and How Does it Work?

A Steering Cylinder is a vital component in many hydraulic systems. It plays a crucial role in vehicle steering mechanisms. This device enables precise control over direction, ensuring safety and ease of operation.

Understanding how a steering cylinder works is essential for both drivers and mechanics. It transforms hydraulic pressure into mechanical motion. Without this component, steering would be cumbersome and inefficient. The design may seem straightforward, yet its function is sophisticated. Many people overlook its importance in everyday driving.

While steering cylinders are reliable, they can fail. Regular maintenance is necessary to avoid issues. Drivers should be aware of potential signs of wear. Recognizing these signs can prevent accidents and costly repairs. Reflecting on the functioning of a steering cylinder may lead us to appreciate the complexity behind simple tasks.

What is a Steering Cylinder? Definition and Overview

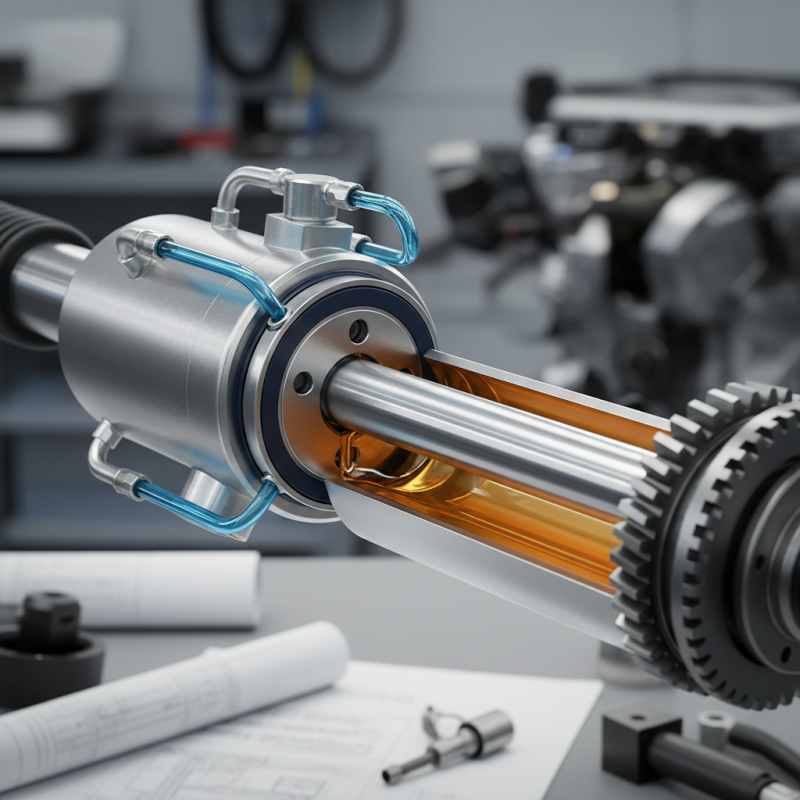

A steering cylinder is a crucial component in hydraulic steering systems. It helps control the direction of a vehicle by converting hydraulic pressure into motion. The cylinder consists of a cylindrical housing, a piston, and hydraulic fluid. When the driver turns the steering wheel, the system directs fluid into the cylinder, pushing the piston. This action rotates the wheels, allowing for precise steering.

Understanding the basic mechanics of a steering cylinder can deepen your knowledge of vehicle dynamics. The hydraulic fluid’s pressure is vital. If there’s a leak or low fluid level, steering can become unresponsive or heavy. Drivers may notice difficulty in turning or unusual noises when the steering system is compromised. Regular maintenance is often overlooked, which can lead to bigger issues down the road.

The design of steering cylinders may appear simple, yet they must withstand significant stress and pressure. Every component plays a role in performance. Even small imperfections can lead to steering failure. It's important to check for wear and tear regularly. Insights into these details can better inform drivers about their vehicles.

The Role of Steering Cylinders in Hydraulic Steering Systems

Steering cylinders are vital components in hydraulic steering systems. They convert hydraulic pressure into mechanical movement. This process helps steer large vehicles with ease. When you turn the steering wheel, hydraulic fluid flows into the steering cylinder. The pressure builds up, pushing the piston inside.

As the piston moves, it activates the steering mechanism. This action provides smooth and responsive handling. Without steering cylinders, maneuvering heavy machinery would be challenging. The precision they offer is crucial in tight spaces. However, if there is a leak or malfunction, performance suffers. Drivers may notice delayed response times or stiff steering.

Regular maintenance is essential to keep steering cylinders functioning well. Inspecting for wear or damage can prevent accidents. Understanding the role of these components highlights their importance. A small issue might lead to significant problems later. So, being attentive can save time and ensure safety on the road. This reinforces the importance of hydraulic systems in modern vehicles.

How Steering Cylinders Operate: Mechanics and Functionality

Steering cylinders play a crucial role in the operation of hydraulic steering systems. These components help transfer force between the driving mechanism and the wheels. When a driver turns the steering wheel, the force is sent to the cylinder, which converts it into linear motion. According to industry reports, approximately 70% of modern vehicles utilize hydraulic steering systems.

The mechanics behind steering cylinders involve a simple hydraulic principle. Pressurized fluid moves within the cylinder to create movement. An internal piston pushes against the fluid, which in turn multiplies force. The design of the cylinder must ensure it is resistant to wear. Reports indicate that durability issues can lead to performance inconsistencies and safety concerns.

Regular maintenance is essential to ensure optimal functionality. Problems such as leaks or poor connections can undermine the entire steering system. Studies show that proper care can extend the lifespan of steering cylinders by up to 25%. There's always room for improvement in the design process as well. Innovations are needed to enhance efficiency and reduce failure rates. The quest for better steering solutions never ends.

Key Specifications and Performance Metrics of Steering Cylinders

Steering cylinders play a crucial role in vehicle control. They provide the necessary force for steering systems, allowing for precise maneuverability. These cylinders work by converting hydraulic pressure into mechanical force. As a result, the driver experiences smoother handling and better feedback from the road.

Key specifications include bore diameter, stroke length, and operating pressure. A larger bore diameter can provide more power, while a longer stroke enhances responsiveness. Operating pressure typically ranges from 1,500 to 3,000 psi, affecting the cylinder’s performance. Monitoring these metrics is essential for optimal function, but often overlooked.

Performance metrics include speed and efficiency. A well-functioning steering cylinder can significantly reduce steering effort. However, if maintenance is neglected, performance can drop. Observing irregularities in steering response often indicates issues. Regular checks on these parameters ensure a reliable steering experience but may be challenging for some.

Applications of Steering Cylinders in Various Industries and Vehicles

Steering cylinders are crucial in various industries and vehicles. They ensure control and precision, especially in heavy machinery and transportation. According to a recent industry report, the global hydraulic cylinder market is expected to reach $7.6 billion by 2025. This growth is driven by increased demand in construction and agriculture sectors. Steering cylinders play a significant role here, providing stability and strength.

In the automotive sector, steering cylinders enhance vehicle maneuverability. They allow smooth turning and improve safety on the road. The U.S. automotive market alone had over 17 million vehicle sales in 2022, emphasizing the importance of reliable steering systems. However, some vehicles still face challenges with steering responsiveness. This inconsistency raises concerns about safety and performance.

In industrial applications, steering cylinders facilitate heavy lifting. They are vital in cranes and forklifts. A report from the International Federation of Robotics reveals that there are over 2.7 million industrial robots in operation worldwide. These robots often rely on precise steering mechanisms to function effectively. Yet, the increasing complexity of industrial environments can lead to failures in these systems, underscoring the need for ongoing improvements and innovations.