How to Select the Right Motorized Valve for Your System?

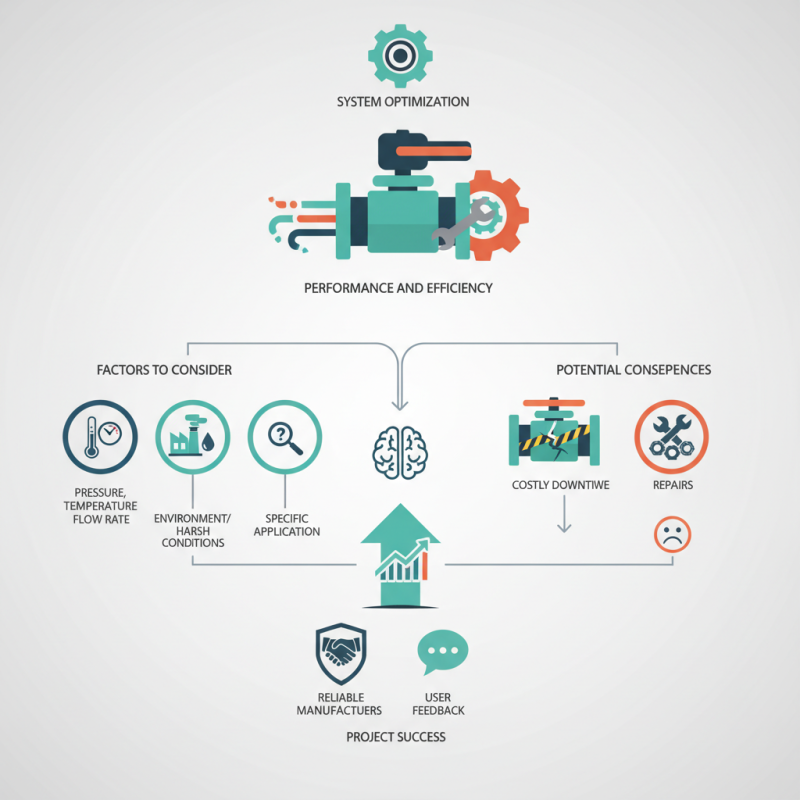

When selecting a Motorized Valve for your system, several factors come into play. The right motorized valve can optimize performance and enhance efficiency. However, choosing the wrong one could lead to costly downtime and repairs.

Consider the specific application you need the motorized valve for. Different systems have unique requirements, such as pressure, temperature, and flow rate. Each of these aspects affects valve selection. Additionally, think about the environment where the valve will be installed. Harsh conditions may require a valve with particular features.

Every system has its quirks. It's essential to reflect on your needs carefully. Don’t rush this decision. A misstep can cause issues down the line. Look for reliable manufacturers and get feedback from users. In the end, a well-chosen motorized valve can make all the difference in your project’s success.

Understanding Motorized Valves and Their Applications

Motorized valves play a crucial role in various systems. They automate the control of fluid flow and pressure. These devices come in different types, including globe, ball, and butterfly valves. Each type serves unique applications. Choosing the right motorized valve can be complex, given the various options available.

Understanding the specific application of a motorized valve is essential. For instance, a ball valve may be ideal for quick shut-off purposes. On the other hand, a globe valve provides precise flow regulation. Factors like pressure, temperature, and fluid type also matter. It's easy to overlook details, which could lead to poor choices.

Installation and maintenance are equally important considerations. An improperly installed valve can lead to leaks or system failures. Regular inspection is vital to ensure performance. Sometimes, even the best valves fail. This highlights the need for continuous learning and adaptation in selecting motorized valves. It's essential to reflect on past experiences to improve future decisions.

Key Factors to Consider When Selecting a Motorized Valve

When selecting a motorized valve for a system, a few key factors stand out. The valve size must match the piping dimensions and flow requirements. A valve that is too small may restrict flow, while one that is too large could lead to inefficiencies. Measurement errors can happen, so double-checking sizes is crucial.

Another important aspect is the type of actuator. Electric, pneumatic, and hydraulic actuators each have their pros and cons. Electric actuators can offer precise control, yet they may struggle in extreme temperatures. In contrast, pneumatic actuators are quick but may require a compressed air source. Evaluating your specific system needs here is vital.

Material selection is often overlooked but essential. The valve materials must resist corrosion and wear based on the fluid type. Choosing the wrong materials can lead to leaks and system failures. It’s a mistake many make, thinking all materials perform the same. Balancing durability with expected conditions is a complex task that deserves careful consideration.

Motorized Valve Selection Factors

Types of Motorized Valves and Their Features

When selecting a motorized valve, understanding its types and features is crucial. Two common types are globe valves and ball valves. Globe valves are known for their throttling ability. They can control flow rates well but may not be the best choice for high-pressure applications. Their complexity can lead to higher maintenance needs over time.

Ball valves, on the other hand, offer quick shut-off capabilities. They are generally simpler and have fewer problems. However, they may not provide the precise flow control that some systems require. Choosing the right type depends on your specific needs. Consider factors such as pressure, flow rate, and application type.

Electric and pneumatic actuators are also important features to consider. Electric actuators can provide precise control but may require more power. Pneumatic actuators are often faster but need a compressed air source. It's easy to overlook these details, but they heavily influence performance and reliability. Reflecting on these choices can help avoid future issues in the system. Choosing the right valve is not just about the initial selection; it's about long-term effectiveness.

How to Select the Right Motorized Valve for Your System? - Types of Motorized Valves and Their Features

| Type of Valve | Operating Mechanism | Common Applications | Features |

|---|---|---|---|

| Globe Valve | Linear Actuation | Flow regulation | Good throttling capabilities |

| Ball Valve | Rotary Actuation | On/off control | Tight seal, fast operation |

| Butterfly Valve | Rotary Actuation | Flow regulation and isolation | Lightweight, space-saving |

| Gate Valve | Linear Actuation | On/off control | Minimal pressure drop, full flow |

| Check Valve | Automatic actuation based on flow | Prevent backflow | Self-acting, reliable |

Evaluating System Requirements for Optimal Valve Selection

Selecting the right motorized valve involves a detailed evaluation of your system's requirements. Consider the flow characteristics first. Is your application high or low flow? Understanding the necessary flow rate is crucial for matching the valve to the system. Pay attention to the pressure drops too. A valve might not perform well if it cannot handle the pressure demands.

Another important factor is the valve's material. Corrosion resistance is vital in many applications. If the fluid has chemicals, select materials that will withstand them. Inadequate material selection can lead to early failure. This might not be evident immediately, but it could impact long-term operations significantly.

Tips: Always involve your team in these evaluations. Fresh perspectives can reveal missing details. Moreover, conduct a risk assessment. Evaluate what happens if a valve fails. This reflection can guide you toward the safest choices for your overall system. Additionally, test the valve under actual operating conditions if possible. It’s a chance to identify potential issues before implementation.

Maintenance and Reliability Considerations for Motorized Valves

When selecting motorized valves, maintenance is often overlooked. Regular checks are vital for longevity. Simple inspections can help identify early signs of wear or malfunction. Keeping the valve clean and free from debris is essential. This requires dedicating time to routine maintenance schedules.

Reliability should be a prime consideration. A valve that fails can disrupt an entire system. It’s crucial to monitor the performance of these components closely. Unexpected leaks or failures can lead to costly repairs and downtime. A maintenance plan should address actuator health and power supply conditions too.

Don't ignore the environmental factors. Harsh conditions can accelerate wear. Ensure the valve selected can withstand the specific environment. Sometimes, users pick valves based on immediate needs without considering long-term impacts. In choosing wisely, one can avoid regrettable decisions later.