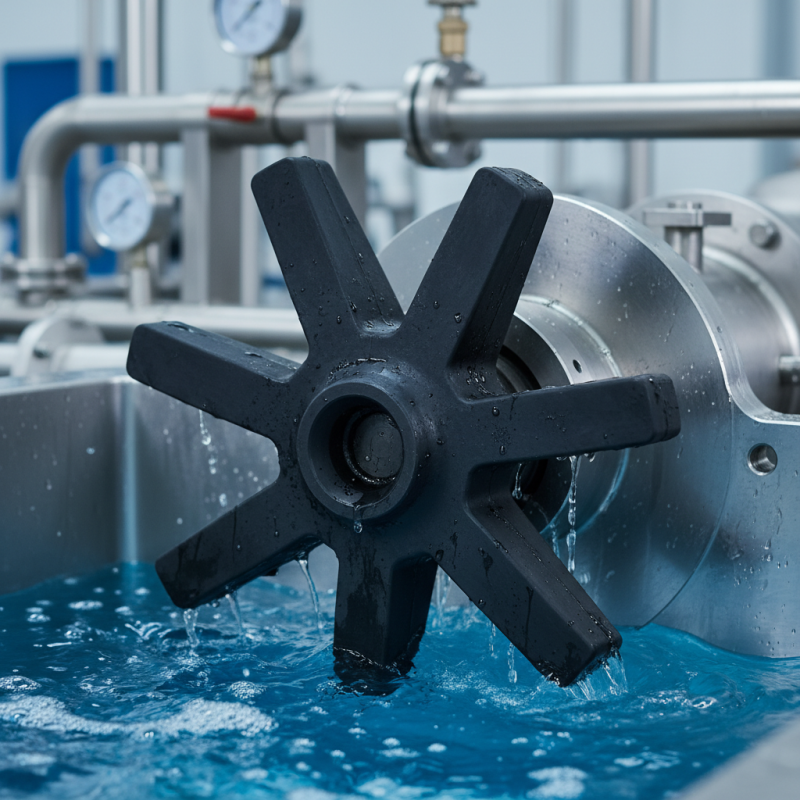

Top 5 Rubber Pump Impeller Benefits You Should Know?

Rubber Pump Impellers are vital components in many industries. They play a significant role in enhancing the efficiency of liquid transfer systems. Understanding their benefits can lead to smarter choices.

One of the main advantages of Rubber Pump Impellers is their durability. They can withstand harsh conditions and resist wear over time. This resilience translates into lower maintenance costs. Additionally, they offer excellent flexibility and can handle a variety of fluids. This adaptability makes them ideal for different applications, from agriculture to chemical processing.

However, not all rubber materials are the same. Choosing the right type for specific needs is crucial. Some may struggle with high temperatures or aggressive chemicals. This reflects the need for careful selection and testing. In the end, recognizing the strengths and limitations of Rubber Pump Impellers is essential for optimal performance.

Advantages of Using Rubber Pump Impellers in Various Applications

Rubber pump impellers are becoming a preferred choice across various industries. They are highly resistant to wear and tear. This durability translates into longer service life. In applications involving corrosive fluids, rubber impellers perform excellently. They prevent damage and reduce maintenance costs significantly.

One advantage is the flexibility of rubber. This feature allows for better performance in fluctuating conditions. If the material of the fluid changes, the rubber can absorb some of the shock. Using a rubber impeller can enhance efficiency in pumping systems. It helps maintain a steady flow, even under pressure.

Tip: When selecting a rubber impeller, consider its compatibility with the fluid types you'll be pumping. You may encounter issues if you overlook this detail.

Another factor to keep in mind is temperature resistance. Some rubber types can handle high temperatures but not all. Ensure you match the impeller with the operational temperatures to avoid failure.

Tip: Regular inspections of the impeller can prevent costly breakdowns. Check for signs of wear, and replace it when needed. This simple step can save you time and money in the long run.

Enhanced Durability and Resistance to Wear in Harsh Environments

Rubber pump impellers stand out for their remarkable durability. They perform well in demanding conditions. This makes them ideal for various industrial applications. The resilience of rubber helps them withstand turbulence and pressure. In harsh environments, their ability to resist wear is crucial.

Using rubber impellers means fewer replacements over time. This results in less downtime for maintenance. They can handle abrasive materials that can damage other types. While they are robust, it's essential to consider temperature limits. High heat may degrade rubber, affecting its effectiveness. Regular checks are still necessary to ensure optimal performance.

In extreme conditions, rubber can flex, allowing for better flow. However, this flexibility can also be a weakness. If the impeller isn’t monitored, it may lead to unexpected failures. Operators must balance benefits with potential risks. Staying proactive in maintenance is key to ensuring long-lasting use.

Improved Efficiency and Performance in Fluid Transfer Systems

Rubber pump impellers play a critical role in enhancing efficiency and performance in fluid transfer systems. According to a recent industry report, systems utilizing rubber impellers can achieve up to 25% more efficient fluid movement compared to traditional materials. This efficiency stems from the flexibility and resilience of rubber, which allows for better adaptability in varying conditions. A rubber impeller can maintain its effective performance across different fluids, mitigating the risk of wear and loss of efficiency.

Performance metrics are often gauged by flow rate and pressure stability. Data suggests that rubber impellers can sustain flow rates that outpace those of metal counterparts by nearly 15%. This advantage is crucial in environments where consistent pressure is vital. However, the material’s performance can decline if not maintained properly, especially under extreme conditions. Regular assessments are recommended to identify wear that may affect overall system functionality.

Visualizing these benefits, it becomes evident that rubber impellers are less prone to cavitation. While cavitation can severely damage a pump’s internals, rubber’s elasticity helps absorb shocks better. Yet, this does not guarantee immunity. Operators must ensure proper alignment and installation to maximize these advantages. Recognizing that every system has its limits is essential for maintaining optimal performance and overcoming any inherent challenges.

Top 5 Rubber Pump Impeller Benefits You Should Know

| Benefit | Description | Impact on Efficiency | Applications |

|---|---|---|---|

| Improved Flow Rate | Enhanced design allows for smoother fluid passage, resulting in a higher flow rate. | Increases productivity in industrial applications. | Water treatment, chemical processing. |

| Durability | Resistant to abrasion and wear, extending the lifespan of the impeller. | Reduces maintenance costs and downtime. | Mining, sewage treatment. |

| Corrosion Resistance | Designed to withstand corrosive environments, preserving performance. | Ensures reliability in harsh chemical applications. | Petrochemical industry, agricultural chemicals. |

| Noise Reduction | Design minimizes vibration and noise during operation. | Creates a more pleasant working environment. | Pumping stations, residential settings. |

| Versatility | Compatible with a wide range of fluids, both viscous and non-viscous. | Increases the range of applications possible with a single pump type. | Food and beverage processing, pharmaceuticals. |

Cost-Effectiveness of Rubber Impellers Compared to Other Materials

Rubber pump impellers are gaining attention for their cost-effectiveness. Unlike metal options, rubber is often less expensive to produce. This makes rubber impellers an attractive choice for budget-conscious projects. Additionally, rubber impellers have lower maintenance costs. They resist wear and tear quite well, saving money in the long run.

However, it is essential to consider the application. In some high-pressure systems, rubber might not perform as effectively as metal. Certain environments may also limit rubber's lifespan. This creates a dilemma. You might save on initial costs but face durability issues later.

Despite these drawbacks, the benefits of rubber impellers cannot be ignored. They are lighter, which can lead to energy savings in pump operations. Furthermore, they are quieter, creating a more pleasant working environment. Balancing these features against their limitations requires careful thought. Ultimately, weighing cost against performance is crucial when selecting the right material.

Cost-Effectiveness of Rubber Impellers Compared to Other Materials

Easy Maintenance and Replacement Benefits of Rubber Impellers

Rubber impellers are gaining popularity in various pumping applications. Their easy maintenance is one of the key benefits. Regular inspections are straightforward and quick. You can often clean them without special tools. This simplicity leads to less downtime and more efficiency. Even if you find wear, replacements are often hassle-free.

Another important aspect is the affordability of rubber impellers. When it’s time for a replacement, they are often cheaper than alternatives. However, the quality can vary, so make sure to choose wisely. Some users may overlook this and end up with subpar options. Replacement processes are typically user-friendly, allowing for quicker repairs. Yet, if not done correctly, this can lead to issues down the line.

Additionally, rubber impellers are less likely to corrode or suffer damage from various chemicals. This resistance contributes to their overall longevity. Maintenance knowledge is essential, though. It helps in identifying potential issues early. Relying solely on their durability might lead to problems. Regular, proactive checks can save time and cost down the road.