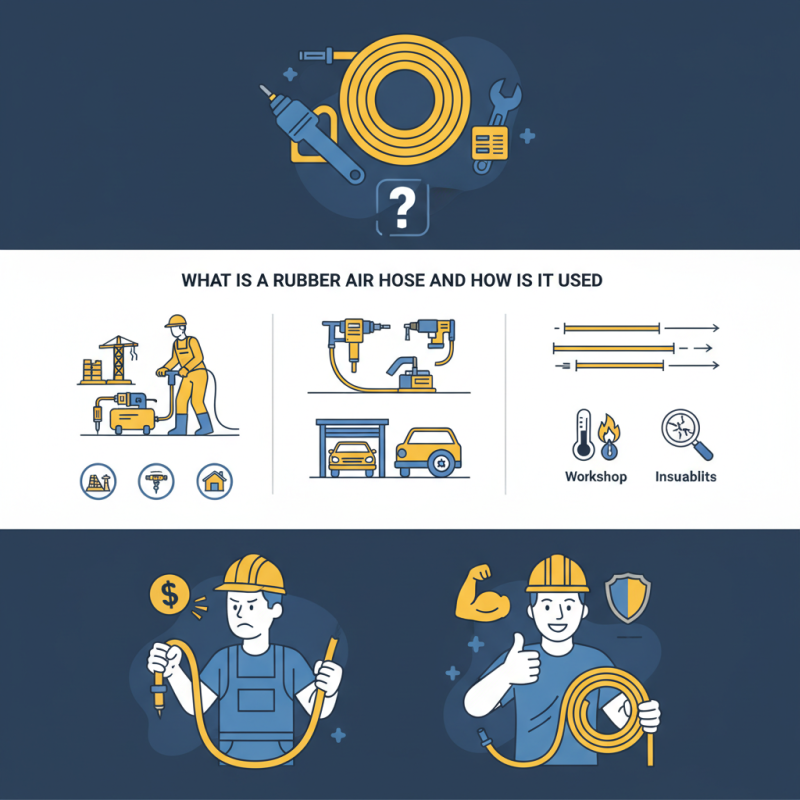

What is a rubber air hose and how is it used?

A rubber air hose is an essential tool in various industries. Its flexibility and durability make it ideal for transporting compressed air. You often find these hoses in construction sites, workshops, and home garages.

These hoses come in various lengths and diameters. This variety allows users to choose the right hose for their equipment. However, selecting the incorrect size can lead to inefficiency. A rubber air hose not only ensures that air flow is smooth, but it also withstands extreme conditions. Still, one must remember to inspect hoses regularly for wear and tear.

Choosing a rubber air hose isn't always straightforward. Users often struggle with finding quality products. Cheaper options might seem tempting but can lead to frustration. Investing in high-quality rubber air hoses pays off in the long run. A well-chosen hose increases productivity and ensures safety during operations.

What is a Rubber Air Hose? Definition and Characteristics

Rubber air hoses are essential in various industries. They are designed to handle compressed air, which is often used in tools and equipment. A typical rubber air hose is flexible, durable, and resistant to wear and tear. This makes it ideal for heavy-duty applications. According to industry reports, the global air hose market is projected to grow by approximately 5% annually.

One key characteristic of rubber air hoses is their temperature resistance. They can work efficiently in diverse weather conditions, ranging from extreme heat to freezing temperatures. The hose's ability to maintain performance under pressure varies. Some hoses can withstand up to 300 PSI, making them suitable for industrial and construction sites. However, not all hoses are created equal. Users must select hoses based on specific needs.

These hoses can sometimes suffer from issues like leaks or cracks. Regular inspections are vital to maintain their integrity. Neglecting maintenance can lead to decreased performance or even accidents. Moreover, the quality of the rubber material can vary widely. Cheaper options may not endure tough working conditions. Hence, careful consideration of rubber quality is essential in purchasing decisions.

What is a Rubber Air Hose and How is it Used?

| Characteristic | Description |

|---|---|

| Material | Made from rubber for flexibility and durability |

| Size | Available in various diameters, typically ranging from 1/4" to 1". |

| Pressure Rating | Can handle pressures up to 300 PSI, depending on the thickness and construction. |

| Temperature Range | Operational temperature typically from -40°F to 150°F. |

| Common Uses | Used in pneumatic tools, air compressors, and automotive applications. |

| Advantages | Lightweight, flexible, resistant to abrasion and weathering. |

| Maintenance | Regularly check for leaks, cracks, and ensure proper storage. |

Common Materials Used in Manufacturing Rubber Air Hoses

Rubber air hoses are essential tools in various industries. They are made from durable materials that withstand high pressure. Common materials for manufacturing include natural rubber, synthetic rubber, and thermoplastic elastomers. Natural rubber offers excellent flexibility but may not resist weather damage. Synthetic rubber, such as nitrile, is often more robust. It provides better oil resistance as well as durability.

The choice of material impacts the hose's lifespan. For instance, thermoplastic elastomers are lightweight and flexible. However, they might not handle extreme temperatures as well as some other options. Careful consideration of these materials is crucial for specific applications. Think about where you will use the hose. Will it be exposed to harsh environments or chemicals? Understanding these details can help you choose the right type.

Remember, using the wrong material can lead to early wear or failure. This can cause safety hazards or inefficiencies. Pay attention to the application needs. It is essential to match the rubber properties to your specific requirements. Ignoring this could result in problems down the line. Choose wisely to ensure optimal performance.

Typical Applications of Rubber Air Hoses in Industry

Rubber air hoses are essential tools in various industrial applications. They are flexible, durable, and can handle high pressure. Many industries rely on these hoses to transport compressed air. This is crucial for tasks like powering pneumatic tools, inflating tires, and operating machinery. In construction and manufacturing, their versatility shines.

One typical application is in automotive repair shops. Mechanics use rubber air hoses for powering impact wrenches. This makes tire changes faster and more efficient. Another common use is in carpentry. Here, they help run nail guns, improving accuracy and speed in woodworking tasks. Such applications reduce manual labor while ensuring high-quality results.

Tips: Always inspect hoses for signs of wear or damage. A small crack can lead to leaks and inefficiency. Keep hoses coiled properly to avoid kinks. Kinks can restrict airflow and lead to premature wear. For storage, avoid placing them in direct sunlight or extreme temperatures. This can judge the longevity of the hoses.

Key Benefits of Using Rubber Air Hoses Compared to Other Types

Rubber air hoses offer several advantages compared to other types. They are durable and flexible. This makes them ideal for various applications. In industries, they withstand extreme temperatures and maintain their performance. According to a recent industry report, rubber hoses can last up to three times longer than PVC hoses. This longevity results in fewer replacements and lower costs over time.

Another benefit is the resistance to abrasion and wear. Rubber air hoses can handle rough environments without degrading quickly. They also resist kinking and twisting when in use. This ensures a continuous air supply during demanding tasks. Data shows that employees who use rubber hoses report fewer interruptions in their workflow.

Tip: Always check the pressure rating of your rubber hose. The right rating ensures safety and effectiveness.

Rubber hoses can be heavier than their counterparts. This might make handling a bit cumbersome. However, many users find that the benefits outweigh this downside. Being mindful of the environment is crucial too. Recycled rubber hoses are an option to explore. They contribute to sustainable practices in the industry.

Tip: Regularly inspect your hose for cracks or wear. Early detection can prevent more significant issues later on.

Maintenance Tips for Ensuring Longevity of Rubber Air Hoses

Rubber air hoses are vital for many applications, from workshops to home projects. Maintaining them is crucial for ensuring their longevity and performance. Regular cleaning helps clear any debris that can build up inside the hose. A quick rinse with water is effective, but make sure they are completely dry before storing them.

Inspecting the hose frequently is essential. Look for signs of wear like cracks or bulges. Even small damages can cause significant issues. Don't overlook these details; they matter. Proper storage is equally important. Keep hoses out of direct sunlight, as UV rays can degrade rubber over time. A coiled hose is easy to store, but be careful not to kink it.

When using the hose, avoid sharp edges and hot surfaces. These can wear the material faster. Using a hose reel can help in managing them. Over time, you’ll notice if maintenance is skipped. Regular check-ups save time and money in the long run. Even a little effort makes a big difference.