Essential Tips for Mastering Plastic Injection Molding Techniques?

Plastic Injection Molding is a vital manufacturing technique. It enables the creation of precise and complex parts. The process offers various advantages, but mastering it requires skill.

Using the right plastic injection mold determines the quality of the final product. Understanding mold design, material selection, and processing parameters is crucial. Many professionals struggle with these aspects. They often overlook the importance of mold maintenance and adjustments.

Mistakes can lead to defects like warpage or surface imperfections. Therefore, careful planning and execution are essential. Balancing speed and quality in production can also be challenging. Reflecting on these common pitfalls can enhance proficiency in plastic injection molding.

Understanding the Basics of Plastic Injection Molding

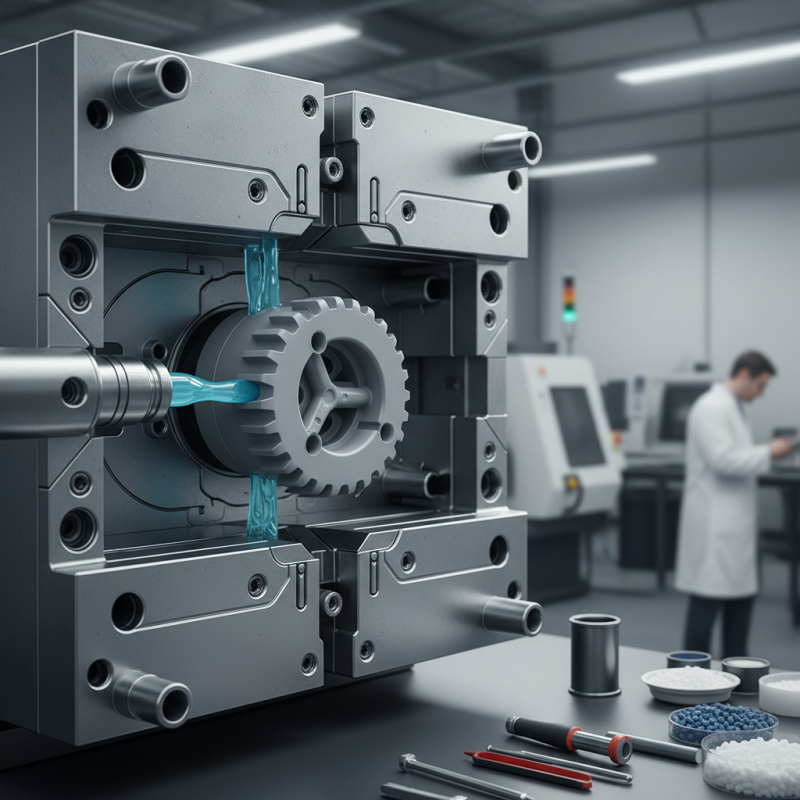

Plastic injection molding is a key manufacturing process. It involves injecting molten plastic into a mold. This method allows for precise shapes and sizes. Understanding the basics is crucial for anyone entering the industry.

The process begins with selecting the right plastic material. Different polymers offer unique properties. For example, some are better for flexibility, while others provide durability. It’s important to test materials beforehand. Small mistakes can lead to significant defects in the final product. Monitoring temperatures during injection is also essential. Too high or too low can affect the molding quality.

Mold design plays a vital role as well. A well-designed mold minimizes scrap material. Yet, many overlook factors like cooling channels and venting. These elements influence cycle times and part integrity. This complexity might seem daunting at first, but mastering it can lead to excellent results. Experimentation often reveals unexpected challenges that require creative solutions.

Key Components of Injection Molding Machines Explained

Injection molding relies on several key components within the machines. Understanding these parts can enhance production quality and efficiency. The injection unit, for example, melts plastic pellets and injects them into the mold. It involves a screw, which can be single or double, pushing the plastic forward. Shortcomings in the screw design can lead to uneven melting and inconsistent product quality.

The clamping unit holds the mold closed during injection. It generates the necessary force to avoid leaks. If the clamping pressure is too low, it may produce defects. The mold itself shapes the final product. A poorly designed mold often results in challenges like surface defects and inaccurate dimensions. Continuous monitoring and adjustments are essential during the injection process.

Cooling systems also play a crucial role. They help solidify the plastic after injection. Inadequate cooling can lead to warping or prolonged cycle times. Troubleshooting these systems can be complex. Many manufacturers struggle to achieve the right balance in cooling duration and temperature. Recognizing these key components can significantly impact the overall mastery of injection molding techniques.

Techniques for Designing Effective Injection Molds

Designing effective injection molds is critical for successful plastic injection molding. A well-designed mold can reduce cycle times and improve part quality. According to a recent industry report, molds account for approximately 20-30% of total production costs. Focusing on mold design helps optimize these expenses.

One vital aspect of mold design is the cooling system. Efficient cooling reduces cycle times and enhances part accuracy. Optimizing the cooling channels can lead to a 30% decrease in cycle time, based on findings from recent studies. However, achieving the ideal layout can be challenging. Designers often face the dilemma of balancing complexity and manufacturability.

Also, consider draft angles in your design. Inadequate draft can lead to defects, impacting production efficiency. Studies reveal that a draft angle of at least 1 degree can significantly ease part removal. Yet, many molds still suffer from insufficient drafting. Ignoring this can lead to higher rejection rates and wasted resources in the long run. Injection mold design is an intricate process that requires attention to detail and a willingness to learn from past mistakes.

Troubleshooting Common Issues in Plastic Injection Molding

Troubleshooting common issues in plastic injection molding is vital for improving production efficiency. Mishaps can occur at any stage. Identifying and addressing them early saves time and resources. Warped parts are a frequent problem. They may result from improper cooling. Checking the cooling channels can help. Inadequate cooling time often leads to this issue. Adjusting the cooling cycles might be necessary.

Another common issue is short shots. This occurs when the mold does not fill completely. It can be caused by insufficient material or low injection pressure. To resolve this, ensure the material supply is adequate. Often, increasing the injection speed helps. Pressure settings may need adjustment as well.

Surface defects are also a concern. These include blemishes and discoloration on final products. They can detract from quality. Causes often relate to material degradation or contamination. Ensuring clean machinery and using high-quality materials is essential. Regular maintenance can prevent these problems. Inconsistent results require reflection on the entire process. Adjustments in scheduling and materials can yield better outcomes.

Best Practices for Material Selection in Injection Molding Processes

Choosing the right materials for injection molding is crucial. The selection process can be overwhelming due to the variety of available options. Each material has its unique properties, which can affect the final product's durability, flexibility, and appearance.

For instance, thermoplastics are popular due to their versatility. They can be remolded through heat, making them easier to work with. However, they may not always provide the strength needed for certain applications. Sometimes, a more rigid material may be required, but then you face challenges in terms of brittleness. Evaluating the specific needs of your project is key.

It's essential to consider factors like temperature resistance and environment. Some materials may perform well in typical conditions but degrade under stress. It's worth running tests before committing to a material choice. Do not overlook the importance of the right additives in altering base material properties. They can improve features, but using too many can complicate the process further. Balancing your choices requires careful planning and a willingness to adapt.

Essential Tips for Mastering Plastic Injection Molding Techniques

This chart displays the best practices for material selection in injection molding processes based on various properties such as tensile strength, flexibility, and temperature resistance.