Mastering Aluminum Window Machinery Techniques for Optimal Production

In the competitive world of manufacturing, mastering the intricacies of Aluminum Window Machinery is essential for achieving optimal production efficiency and quality. This tutorial aims to guide both newcomers and seasoned professionals through the essential techniques and best practices involved in operating aluminum window machinery. From understanding the fundamental components to employing advanced techniques for precision cutting and assembly, this resource is designed to enhance your manufacturing process. By delving into the intricacies of machinery operation, maintenance, and troubleshooting, we will provide the knowledge necessary to maximize productivity while minimizing waste. Join us on this journey to enhance your skills and elevate your production capabilities in the aluminum window industry.

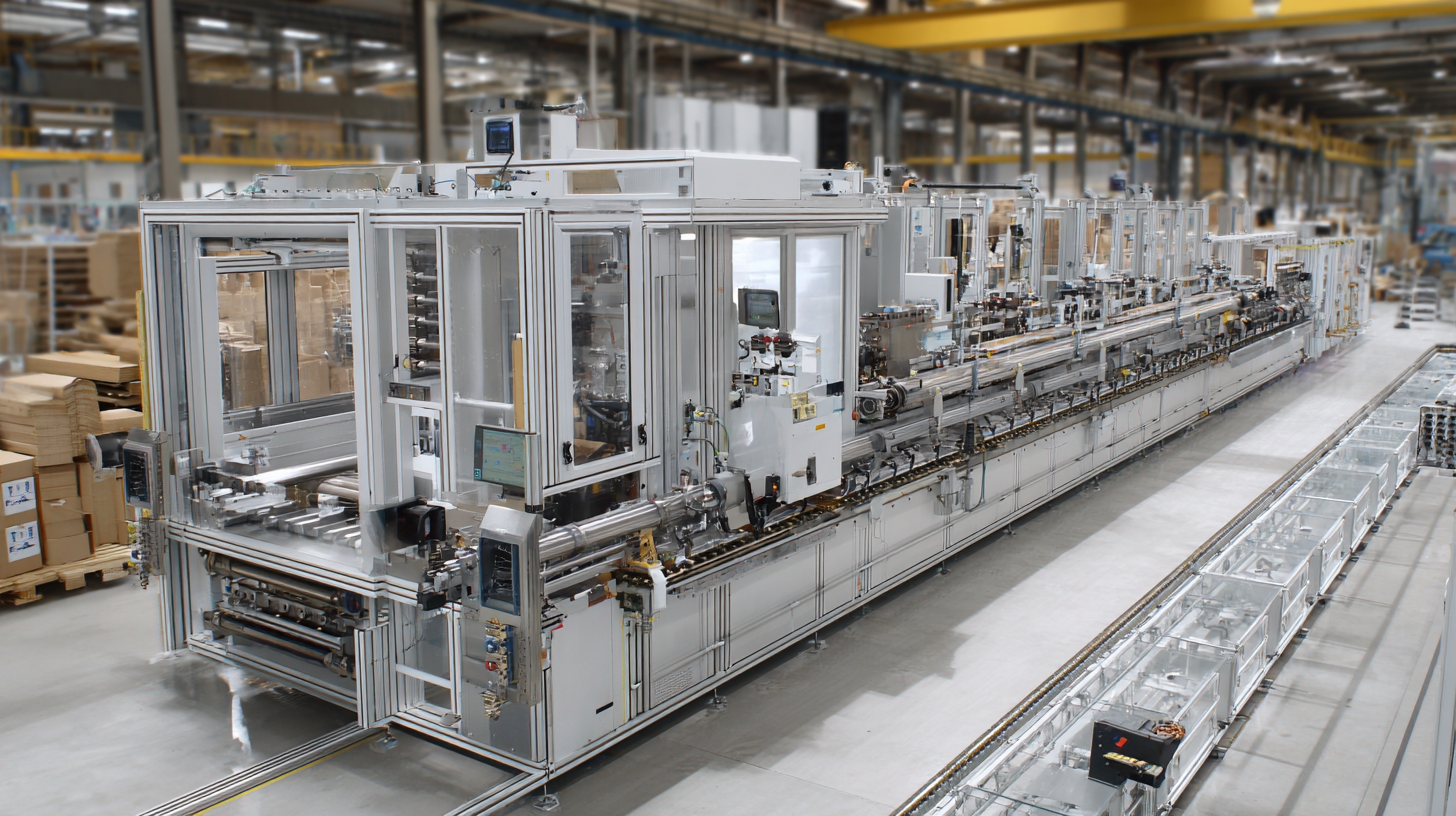

Understanding the Basics of Aluminum Window Machinery Operations

Understanding the fundamentals of aluminum window machinery operations is crucial for manufacturers aiming to enhance efficiency and output quality. Aluminum window production involves a series of steps, including cutting, shaping, and assembling various components, all of which rely on specialized machinery. Familiarity with these machines not only ensures smoother operation but also minimizes errors and waste. For instance, understanding how to properly calibrate cutting machines can lead to more accurate dimensions, which directly affects the overall performance of the final product.

Moreover, regular maintenance and monitoring of the machinery are essential aspects that contribute to optimal production. Operators must be trained to recognize potential issues early, such as unusual noises or vibrations, which could indicate a malfunction. By implementing a routine inspection schedule, manufacturers can maintain the integrity of their machinery, thus preventing breakdowns that could disrupt production timelines. Furthermore, investing time in understanding software controls, which manage production schedules and machine settings, can significantly streamline operations and improve workflow efficiency.

Key Techniques for Enhancing Precision in Window Production

When it comes to aluminum window production, precision is paramount. Utilizing advanced machinery techniques can significantly enhance the quality and fit of your windows. One key technique is to regularly calibrate your equipment to ensure that dimensions remain consistent throughout the production process. This not only improves accuracy but also reduces material waste, ultimately increasing your bottom line.

Another essential tip for achieving precision is to implement a rigorous quality control system. Establish regular checkpoints within the production cycle to examine the dimensions and integrity of each window. By catching potential issues early, you can ensure that the final product meets the exact specifications and industry standards.

Additionally, investing in employee training on the latest machinery advancements can make a substantial difference. Skilled operators are more likely to spot anomalies and adjust settings for optimal performance. Encourage your team to engage in continuous learning, as staying updated on machinery techniques can lead to improved production efficiency and higher quality outcomes.

Mastering Aluminum Window Machinery Techniques for Optimal Production

| Technique | Description | Impact on Precision | Recommended Machinery |

|---|---|---|---|

| Profile Cutting | Precision cutting of aluminum profiles using CNC machines to ensure exact dimensions. | High accuracy in profile dimensions, reducing waste. | CNC Profile Cutters |

| Corner Welding | Automated welding techniques to securely join window corners. | Ensures strong and clean welds, maintaining window integrity. | Pneumatic Corner Welding Machines |

| Sealing and Glazing | Application of seals and glazing solutions with precision machinery. | Improves thermal performance and reduces air leaks. | Automated Sealing Machines |

| Quality Control | Regular inspection processes using measurement tools to ensure adherence to specifications. | Early detection of defects enhances final product quality. | Measurement Gauges and Inspection Tools |

| Assembly Techniques | Best practices for assembling window components for durability and ease of installation. | Increases assembly efficiency and reduces installation errors. | Assembly Jigs and Fixtures |

Innovative Solutions for Streamlining Aluminum Processing Workflows

In the fast-evolving landscape of aluminum processing, innovative solutions play a pivotal role in streamlining workflows and enhancing production efficiency. Recent advancements highlight the significance of integrating digital tools and automation in the industry. For instance, emerging software solutions are simplifying the reverse engineering of parts, thus reducing production lead times and allowing manufacturers to quickly adapt to design changes.

As the market leans towards digitalization, companies are setting new standards for design and manufacturing processes. The introduction of comprehensive 3D libraries facilitates seamless integration within architectural designs, enabling architects and engineers to access a wealth of aluminum profiles without the cumbersome manual searches. Moreover, initiatives promoting automation in metal processing further decrease operational complexity, ultimately leading to lower costs and improved productivity. Streamlining aluminum processing is not just about optimizing existing workflows; it encompasses adopting innovative technologies that drive efficiency and foster growth in a competitive market.

Troubleshooting Common Issues with Aluminum Window Machinery

When working with aluminum window machinery, troubleshooting common issues is crucial for maintaining optimal production levels. According to a recent industry report by the Window & Door Manufacturers Association, over 30% of production delays stem from machinery malfunctions, highlighting the importance of regular maintenance and prompt troubleshooting. Common problems include misalignment, inconsistent cutting lengths, and hydraulic failures. Recognizing these issues early can prevent costly downtime and ensure a smoother workflow.

Tip 1: Regularly inspect machinery for signs of wear and tear. Small adjustments may prevent larger issues later. For example, ensuring that all cutting blades are sharp and correctly aligned can significantly enhance precision and reduce waste.

Tip 2: Keep a log of all maintenance and repairs performed on the machinery. This can help in identifying repetitive problems and patterns, allowing for proactive measures that save time and resources. The National Institute of Standards and Technology emphasizes that implementing a solid maintenance plan can increase machinery lifespan by up to 25%.

By understanding and addressing these common issues effectively, manufacturers can minimize interruptions in their production processes and maintain a competitive edge in the aluminum window industry.

Best Practices for Maintenance and Longevity of Production Equipment

Maintaining aluminum window machinery is crucial for achieving optimal production and ensuring the longevity of equipment. Regular maintenance practices can significantly reduce downtime and enhance efficiency. One of the best practices is to establish a routine inspection schedule. This should include checking for wear and tear on essential components, ensuring that all moving parts are properly lubricated, and identifying any potential issues before they escalate. Investing time in this preventive approach not only saves costs in the long run but also contributes to a smooth production flow.

Another essential practice involves adhering to the manufacturer's guidelines for operation and maintenance. Each machine comes with specific requirements that are tailored to its design and function. By following these guidelines, operators can avoid common pitfalls that lead to equipment malfunction. Additionally, training staff on proper usage and care of the machinery is vital. Empowering the workforce with knowledge about handling equipment responsibly can lower the risk of accidents and prolong the machinery's lifecycle. Ultimately, these maintenance strategies foster a productive environment and contribute to the overall success of aluminum window manufacturing.