Discover the Innovations in Window Making Equipment Transforming the Industry

In the ever-evolving realm of manufacturing, innovations in Window Making Equipment play a pivotal role in transforming the industry, enhancing efficiency and precision. As the demand for high-quality, sustainable windows continues to rise, manufacturers are increasingly turning to advanced technologies that not only streamline production processes but also improve product durability and performance. This exploration of modern advancements reveals cutting-edge machinery and techniques, from automated assembly lines to smart manufacturing solutions, that are reshaping the landscape of window making.

By integrating these innovations, companies are not only meeting market demands but also pushing the boundaries of what is possible in design and functionality. Join us as we delve into the significant breakthroughs in Window Making Equipment, examining how they are revolutionizing production practices and setting new industry standards.

Exploring Advanced Automation Techniques in Window Manufacturing Equipment

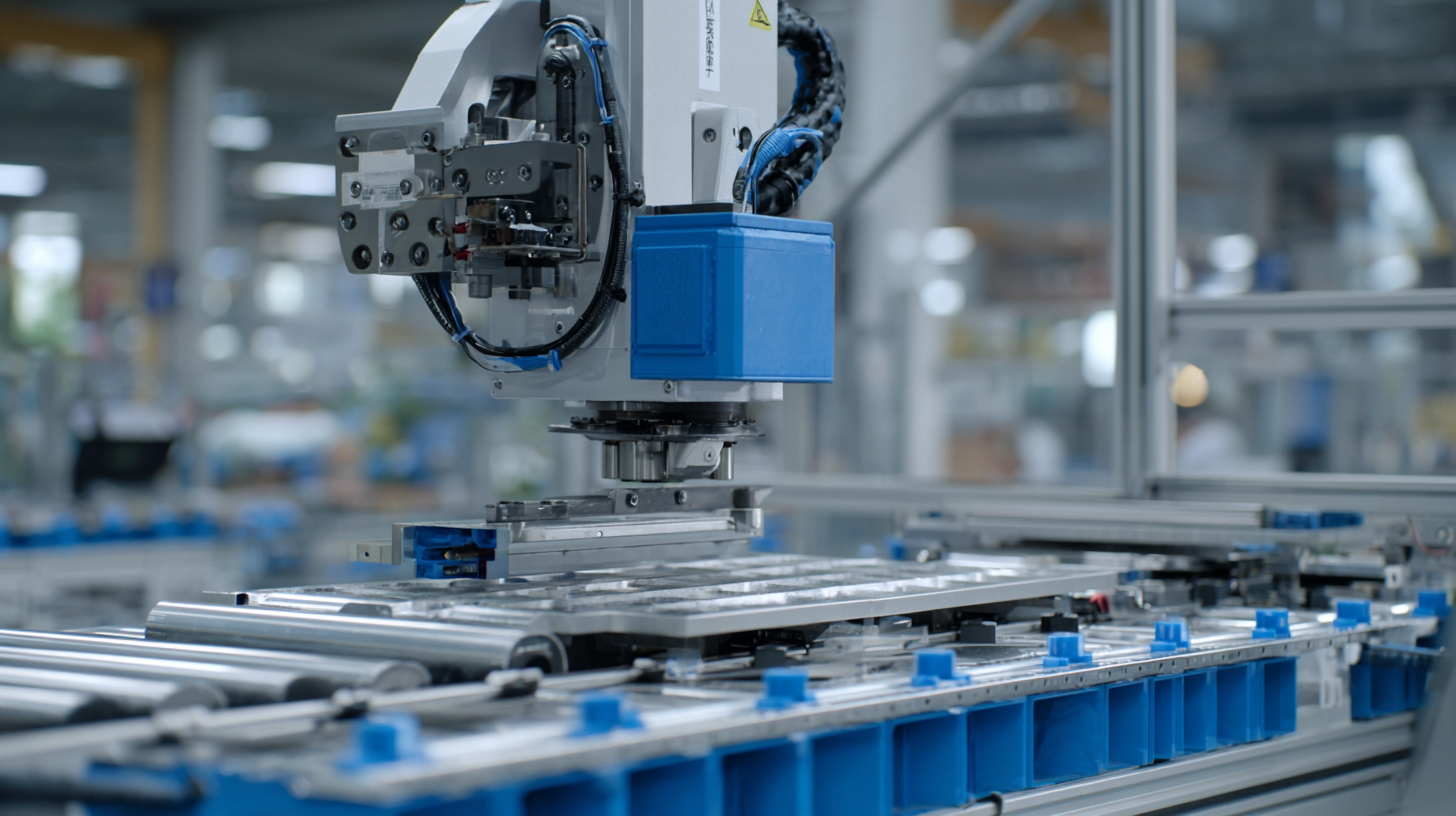

The integration of advanced automation techniques in window manufacturing equipment is reshaping the industry's landscape. As companies adopt digital manufacturing technologies, productivity levels rise significantly, streamlining processes that were once labor-intensive and time-consuming.

Automation not only enhances efficiency but also reduces the risk of human error, allowing manufacturers to focus on quality and innovation.

The implementation of machine-learning applications further accelerates this transformation by enabling predictive analytics in manufacturing. For instance, tools that analyze production data can help pinpoint inefficiencies, allowing manufacturers to optimize their operations proactively. Such innovations are essential in an increasingly competitive market, making automation a critical investment for those aiming to excel in window manufacturing.

The implementation of machine-learning applications further accelerates this transformation by enabling predictive analytics in manufacturing. For instance, tools that analyze production data can help pinpoint inefficiencies, allowing manufacturers to optimize their operations proactively. Such innovations are essential in an increasingly competitive market, making automation a critical investment for those aiming to excel in window manufacturing.

The convergence of these technologies is paving the way for smarter, more agile production environments where responsiveness to market demands is elevated, ultimately leading to superior products and increased customer satisfaction.

The Role of Smart Technology in Enhancing Window Production Efficiency

The integration of smart technology in window manufacturing has revolutionized production efficiency, presenting an array of innovations that streamline operations. Automation and advanced robotics are pivotal in reducing lead times and minimizing human error during the window making process. These technologies not only optimize labor costs but also ensure that each component meets strict quality standards. AI-driven machines can analyze production data in real-time, adapting operations to enhance speed and accuracy while also predicting maintenance needs, significantly reducing downtime.

The integration of smart technology in window manufacturing has revolutionized production efficiency, presenting an array of innovations that streamline operations. Automation and advanced robotics are pivotal in reducing lead times and minimizing human error during the window making process. These technologies not only optimize labor costs but also ensure that each component meets strict quality standards. AI-driven machines can analyze production data in real-time, adapting operations to enhance speed and accuracy while also predicting maintenance needs, significantly reducing downtime.

Additionally, smart technology enables manufacturers to connect their production lines to the Internet of Things (IoT), allowing for seamless communication between equipment. This connectivity provides valuable insights into operational performance, enabling manufacturers to make informed decisions based on data analytics. By implementing smart sensors and monitoring systems, companies can track energy consumption and waste, leading to more sustainable practices and cost savings. As the industry continues to embrace these innovations, the role of smart technology in window production will only grow, driving further advancements in efficiency and quality.

Innovative Materials Transforming Window Crafting: A Look at Industry Trends

The window making industry is experiencing a significant transformation thanks to innovative materials that are reshaping the craftsmanship involved in window manufacturing. According to a recent report by Research and Markets, the global window and door manufacturing market is expected to surpass $300 billion by 2025, driven by advances in materials like fiberglass and composite materials. These innovations are not just enhancing the aesthetic appeal of windows but also improving their energy efficiency and durability.

Furthermore, the trend towards sustainable building solutions has led to the increased use of recycled materials in window production. A study by Grand View Research indicates that the use of eco-friendly materials in the construction sector is gaining traction, with over 60% of builders now prioritizing sustainable products. This shift not only meets consumer demand for greener options but also helps contractors to comply with stricter environmental regulations, showcasing how innovative materials are pivotal to the future of window crafting in the industry.

Evaluating Energy-Efficient Equipment in the Window Making Sector

In the window making industry, energy efficiency is becoming a core consideration as manufacturers strive to reduce their carbon footprint and meet growing market demands. Innovations in technology have led to the development of equipment that not only enhances production speed but also optimizes energy use. For example, the integration of advanced glazing systems and automated cutting machines allows for precise handling of materials, resulting in minimal waste and improved thermal insulation in the final products.

Tips: When evaluating energy-efficient equipment for window making, consider the long-term return on investment rather than just the initial costs. Machines that utilize smart technology can adjust their operations based on real-time data, ensuring optimal performance while conserving energy. Additionally, look for suppliers who provide energy Star-rated products, as these are often designed to meet strict energy efficiency guidelines.

Moreover, implementing equipment that supports renewable energy sources, like solar power, can greatly benefit manufacturers by reducing operational costs. As the industry evolves, moving towards energy-efficient solutions will be pivotal for businesses aiming to remain competitive and environmentally responsible while meeting stringent regulations.

Discover the Innovations in Window Making Equipment Transforming the Industry - Evaluating Energy-Efficient Equipment in the Window Making Sector

| Equipment Type | Energy Efficiency Rating | Average Power Consumption (kW) | Production Capacity (Units per Hour) | Key Innovations |

|---|---|---|---|---|

| Automated Cutting Machine | A+ | 3.2 | 150 | Laser-guided precision cutting |

| Insulation Material Applicator | A++ | 2.5 | 100 | Eco-friendly materials integration |

| Multi-functional Welding Machine | B | 4.0 | 80 | Automatic temperature control |

| Sealing and Packaging Unit | A+++ | 1.8 | 120 | Smart sealing technology |

| Window Assembly Line | A+ | 3.5 | 200 | Robotic arms for precision assembly |

Impact of Digital Tools on Precision and Quality Control in Window Manufacturing

The window manufacturing industry is undergoing a significant transformation driven by digital tools that enhance precision and quality control. According to a recent report by Smithers Pira, the adoption of advanced technologies in window manufacturing processes has led to a reduction in production errors by approximately 30%. Digital tools such as computer-aided design (CAD) software and three-dimensional (3D) printing are enabling manufacturers to create more precise measurements and intricate designs, resulting in a superior end product.

Moreover, the integration of Internet of Things (IoT) devices allows for real-time monitoring of production lines, making it easier to identify and rectify issues before they escalate. Studies indicate that manufacturers leveraging IoT technologies can improve their efficiency by up to 25%, thanks to automated adjustments based on data analytics. This transformation not only enhances product quality but also streamlines operations, reducing waste and manufacturing costs.

**Tip:** To stay competitive in the evolving market, window manufacturers should invest in training their workforce on these digital tools, ensuring that employees are skilled in utilizing technologies like CAD and IoT for better outcomes. Additionally, regular audits of production processes with data analytics can optimize workflows and enhance overall precision in manufacturing.

Impact of Digital Tools on Precision and Quality Control in Window Manufacturing

Related Posts

-

The Future of Innovative Wood Window Manufacturing Equipment: Revolutionizing Production Efficiency

-

7 Best Innovations in Window Machinery for 2024

-

Maximizing Efficiency: Optimizing Your Aluminium Door Window Manufacturing Process

-

Unlocking Efficiency in Aluminium Window Manufacturing with Advanced Fabrication Machines

-

Maximizing Efficiency with PVC Window Welding Machines Through Reduced Maintenance Costs and Enhanced Support

-

Top 10 Manufacturers of Aluminum Window Making Machines from China at the 137th Canton Fair