Revolutionizing Efficiency: The Latest Innovations in Window Making Equipment for Global Buyers

In today's competitive market, the demand for advanced manufacturing technologies has never been more crucial, especially within the window making industry. According to a recent report by Grand View Research, the global window and door manufacturing market was valued at approximately $232 billion in 2022, and it is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth presents a significant opportunity for manufacturers to invest in state-of-the-art Window Making Equipment that promises to enhance production efficiency, reduce waste, and lower operational costs.

As the industry evolves, innovations in window making equipment play a vital role in meeting the ever-increasing standards for energy efficiency and sustainability. The introduction of automated systems and smart technology not only streamlines manufacturing processes but also ensures compliance with environmental regulations. A recent survey from the National Association of Manufacturers reported that nearly 80% of manufacturers believe that adopting advanced technologies could significantly improve their productivity and market competitiveness. As we delve into the latest innovations, it becomes clear that modernizing production facilities with innovative window making equipment is essential for staying ahead in an evolving landscape.

Cutting-Edge Technologies Transforming Window Manufacturing Processes

The window manufacturing industry is undergoing a significant transformation, driven by cutting-edge technologies that enhance efficiency and streamline production processes. According to a recent report by Smithers Pira, the global market for window-making equipment is projected to reach $5.2 billion by 2025, highlighting the urgent need for manufacturers to adopt innovative solutions to stay competitive. Automation and robotics are leading the charge, with companies integrating advanced machinery that can produce higher volumes with reduced labor costs. For instance, automated cutting and assembly systems can complete tasks at speeds previously unimaginable, thereby minimizing human error and maximizing output. Furthermore, the implementation of advanced materials is revolutionizing the way windows are produced. The introduction of high-performance glass and energy-efficient frames has not only improved product durability but also enhanced energy performance ratings. According to the National Renewable Energy Laboratory (NREL), energy-efficient windows can reduce heat loss by up to 30%, reflecting the industry's shift towards sustainability. Manufacturers are increasingly embracing digital technologies, such as 3D printing and IoT, which allow for greater customization and real-time monitoring of production lines. These innovations are not just enhancing the efficiency of the window-making process; they are also responding to evolving consumer demands for sustainable and aesthetically pleasing products. As global buyers seek high-quality windows that meet stringent energy standards, manufacturers must leverage these cutting-edge technologies to innovate and improve their offerings continually. The integration of data analytics in manufacturing processes allows for predictive maintenance, ensuring that equipment operates at peak efficiency, further solidifying the industry's move towards a smarter, more responsive manufacturing landscape.

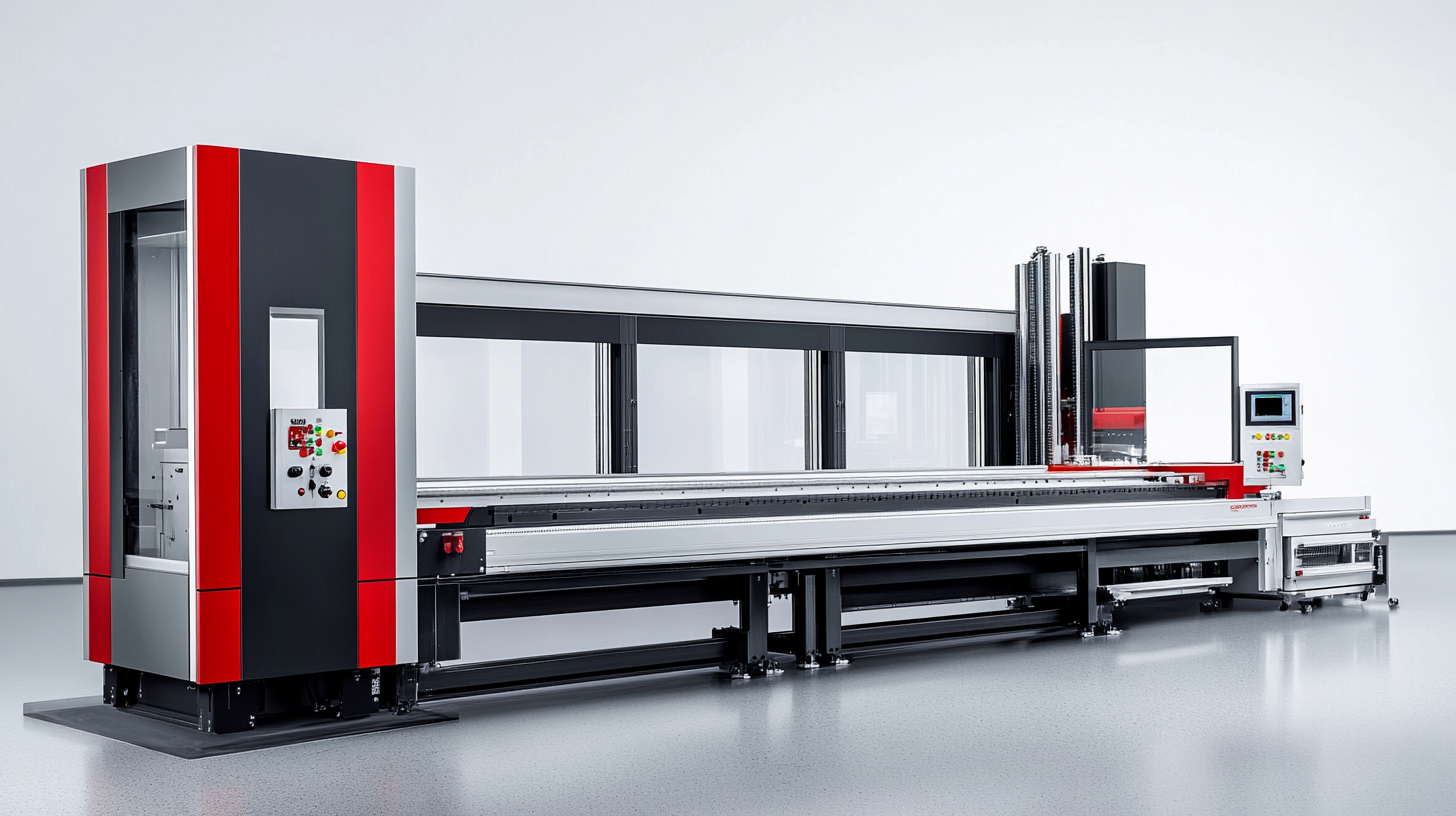

Enhancing Precision: The Role of Automation in Window Equipment

The window manufacturing industry is undergoing a significant transformation, driven by advancements in automation technology. As global buyers seek to enhance their production efficiency, the integration of automated systems in window making equipment has emerged as a game changer. These innovations not only streamline the manufacturing process but also ensure precise measurements and high-quality outputs, critical for meeting the demands of modern construction.

Automation plays a pivotal role in enhancing accuracy throughout various stages of window production. From cutting and shaping materials to assembling the final product, automated machinery reduces the margin for human error, resulting in superior precision. Additionally, real-time data analytics provided by these systems enable manufacturers to monitor performance and adjust operations swiftly, ensuring that production aligns with evolving market demands.

Moreover, this shift towards automated solutions reflects a broader trend in manufacturing, where speed and quality are paramount. By utilizing advanced robotics and machine learning, window manufacturers can optimize their workflows, reduce waste, and increase overall output. As a result, companies that embrace these technological advancements are well-positioned to meet the increasingly stringent requirements of global buyers while maintaining a competitive edge in the marketplace.

Sustainable Practices: Eco-Friendly Innovations in Window Production

In recent years, the window manufacturing industry has witnessed a significant shift towards sustainable practices. As global buyers increasingly prioritize eco-friendly materials, manufacturers are adopting innovative technologies that minimize environmental impact. According to a report by the U.S. Department of Energy, window production is responsible for approximately 3% of the total energy consumption in the manufacturing sector. This statistic highlights the urgent need for advancements in energy-efficient production processes.

One notable innovation is the integration of recycled materials into window manufacturing. Data from the National Association of Home Builders shows that using recycled glass can reduce energy consumption by 20% compared to traditional glass production methods. Furthermore, advancements in frame materials, such as vinyl and thermal aluminum, have been enhanced to improve insulation and reduce energy loss. These developments not only help decrease the carbon footprint of window production but also create high-performance products that meet the demands of eco-conscious consumers.

Additionally, the use of water-based adhesives and low-VOC coatings is gaining traction in the industry. Research indicates that adopting these eco-friendly alternatives can lower harmful emissions by up to 50% during production. As a result, manufacturers are not only contributing to a healthier ecosystem but also enhancing indoor air quality for consumers. These innovations reflect a broader trend within the industry, where sustainable practices are becoming a cornerstone of competitiveness and market appeal in the global landscape of window manufacturing.

Global Market Trends Driving the Demand for Advanced Window Technologies

The global market for window technologies is undergoing a significant transformation, driven by advancements in efficiency and sustainability. According to a recent report by MarketsandMarkets, the window and door market is projected to reach $300 billion by 2025, growing at a CAGR of 5.5% from 2020. This growth is largely attributed to increasing consumer demand for energy-efficient homes and buildings, alongside stricter regulations on energy performance.

Recent innovations in window-making equipment, such as automated cutting and sealing systems, are facilitating this shift. These technologies not only enhance precision but also reduce waste, aligning with the sustainable practices sought by both manufacturers and consumers. A study by Research and Markets highlighted that smart windows, which can adjust their tint based on sunlight exposure, are gaining traction and expected to account for over 10% of the residential window market by 2024. This trend indicates a clear demand for advanced technologies that promote energy savings.

Furthermore, the integration of IoT (Internet of Things) in window technology is emerging as a critical trend. Real-time data collection and analytics enable manufacturers to optimize production processes and improve product performance. The global smart window market alone is anticipated to grow from $6.5 billion in 2020 to $15 billion by 2026, as noted by a report from Fortune Business Insights. This surge demonstrates how connected technologies are revolutionizing the window-making industry, meeting the modern buyer's aspirations for efficiency and smart living solutions.

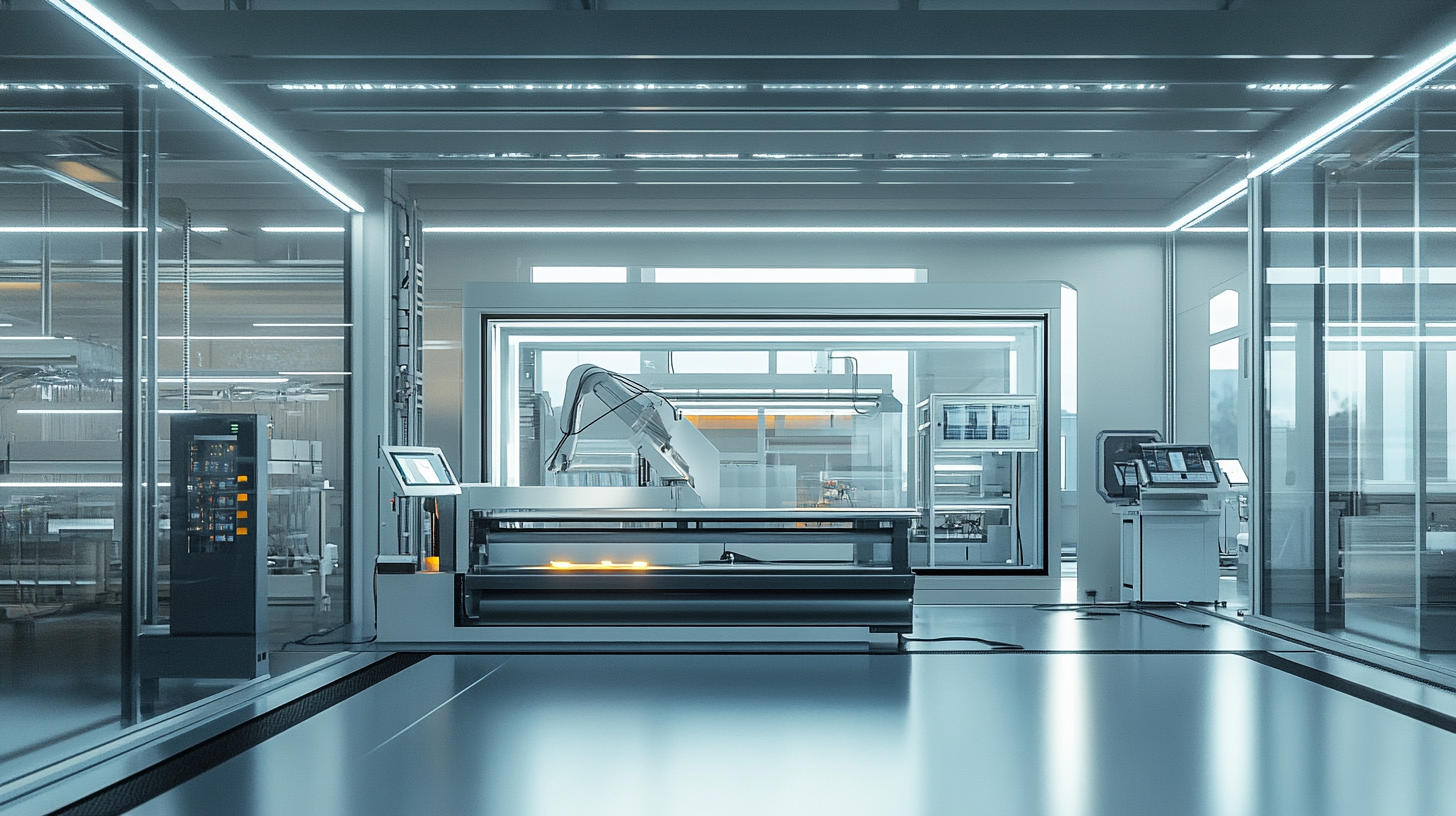

Integrating Smart Solutions: IoT and AI in Window Manufacturing Equipment

In the rapidly evolving landscape of window manufacturing, integrating smart solutions such as the Internet of Things (IoT) and Artificial Intelligence (AI) is transforming traditional processes into efficient, data-driven operations. Manufacturers are increasingly embracing IoT-enabled equipment that allows for real-time monitoring and control of machinery, enhancing productivity and reducing downtime. By connecting devices and sensors, companies can collect valuable data on equipment performance and environmental conditions, enabling proactive maintenance and quicker responses to any operational issues.

AI algorithms play a crucial role in optimizing production processes as well. These smart systems analyze vast amounts of data to identify patterns and make informed decisions that improve efficiency. For instance, AI can predict demand fluctuations, allowing manufacturers to adjust their production schedules accordingly. Moreover, AI-driven analytics assist in quality control by identifying defects early in the manufacturing process, thereby reducing waste and ensuring that only the highest quality windows reach consumers.

The adoption of these technologies not only streamlines operations but also leads to significant cost savings and improved sustainability. As window manufacturers look to meet global demands, the integration of IoT and AI stands out as a key strategy for enhancing competitiveness in a crowded market. As innovations continue to evolve, the focus on smart solutions will pave the way for a new era in window manufacturing, characterized by greater efficiency and responsiveness to client needs.