The Future of Best Thermal Break Machines in 2025 Global Trends to Watch

As we advance into 2025, the thermal break machine industry is expected to witness significant transformation driven by technological innovations and evolving market demands. According to a recent market research report by Allied Market Research, the global thermal break material market is projected to reach USD 2.57 billion by 2025, growing at a CAGR of 6.5% from 2020. This surge indicates a robust appetite for efficient thermal insulation solutions, rendering advanced thermal break machines essential for manufacturers aiming to enhance energy efficiency in building structures. Key strategies for success will revolve around integrating automated processes, utilizing sustainable materials, and improving production efficiency. By embracing these trends, businesses can position themselves at the forefront of this dynamic market, ensuring their thermal break machines meet the future's rigorous standards and expectations.

The Evolution of Thermal Break Technology: Key Innovations Leading to 2025

The evolution of thermal break technology has been driven by the need for enhanced energy efficiency and sustainability in building materials. In recent years, innovations such as advanced composite materials and improved manufacturing processes have emerged, significantly boosting the performance of thermal break machines. As we move towards 2025, the integration of smart technology in thermal break systems is expected to take center stage, allowing for real-time monitoring and optimization of insulation properties.

Moreover, the shift towards environmentally friendly practices is reshaping the landscape of thermal break technology. Manufacturers are increasingly focusing on recyclable materials and energy-efficient designs, aligning with global sustainability goals. The introduction of automated production lines equipped with AI-driven analytics will further streamline operations and reduce waste, setting new standards for efficiency in the industry. These trends not only enhance the effectiveness of thermal breaks but also contribute to the overall reduction of carbon footprints in new constructions.

Global Market Dynamics: How Trade Policies Impact Thermal Break Manufacturing

In 2025, the thermal break manufacturing industry is poised for significant transformation influenced by evolving global trade policies. Governments worldwide are increasingly recognizing the importance of energy efficiency and insulation in construction materials, which has prompted the establishment of stringent regulations and standards. These policies not only aim to reduce carbon emissions but also create a more competitive market for thermal break machines, urging manufacturers to enhance their technological capabilities. Companies that can adapt quickly to these changes will likely gain a substantial advantage over their competitors.

Furthermore, the interaction of trade agreements and tariffs will play a crucial role in shaping the landscape of thermal break production. As countries negotiate deals that promote sustainable practices, manufacturers will have to navigate the complexities of international trade compliance. This dynamic environment presents both challenges and opportunities; manufacturers may find new markets opening while simultaneously facing increased scrutiny over their environmental practices. The ability to remain agile in response to such changes will be vital for companies looking to thrive in the global marketplace.

Sustainability in Thermal Break Production: Trends Driving Eco-Friendly Solutions

As we look ahead to 2025, sustainability is set to play a pivotal role in the thermal break production industry. With increasing awareness around climate change and resource conservation, manufacturers are focusing on eco-friendly materials and processes. This shift not only aligns with global sustainability goals but also attracts environmentally conscious consumers, driving market demand for greener solutions. Companies are now exploring bio-based thermal break products that reduce environmental impact while maintaining performance.

Tip: When considering thermal break machines, prioritize those that offer sustainable production practices and materials. Look for manufacturers that incorporate recycled materials or have a transparent supply chain that supports eco-friendly initiatives.

Furthermore, advancements in technology are enabling smarter production techniques, such as automated systems that minimize waste and energy consumption. Integrating these innovations can enhance efficiency, reduce operating costs, and support a company's green credentials. With legislation increasingly favoring sustainable practices, adapting to these trends not only fulfills regulatory requirements but also positions businesses as leaders in the thermal break industry.

Tip: Invest in technologies that allow for better energy management within your thermal break operations. This not only reduces costs but also plays a significant role in lowering your carbon footprint.

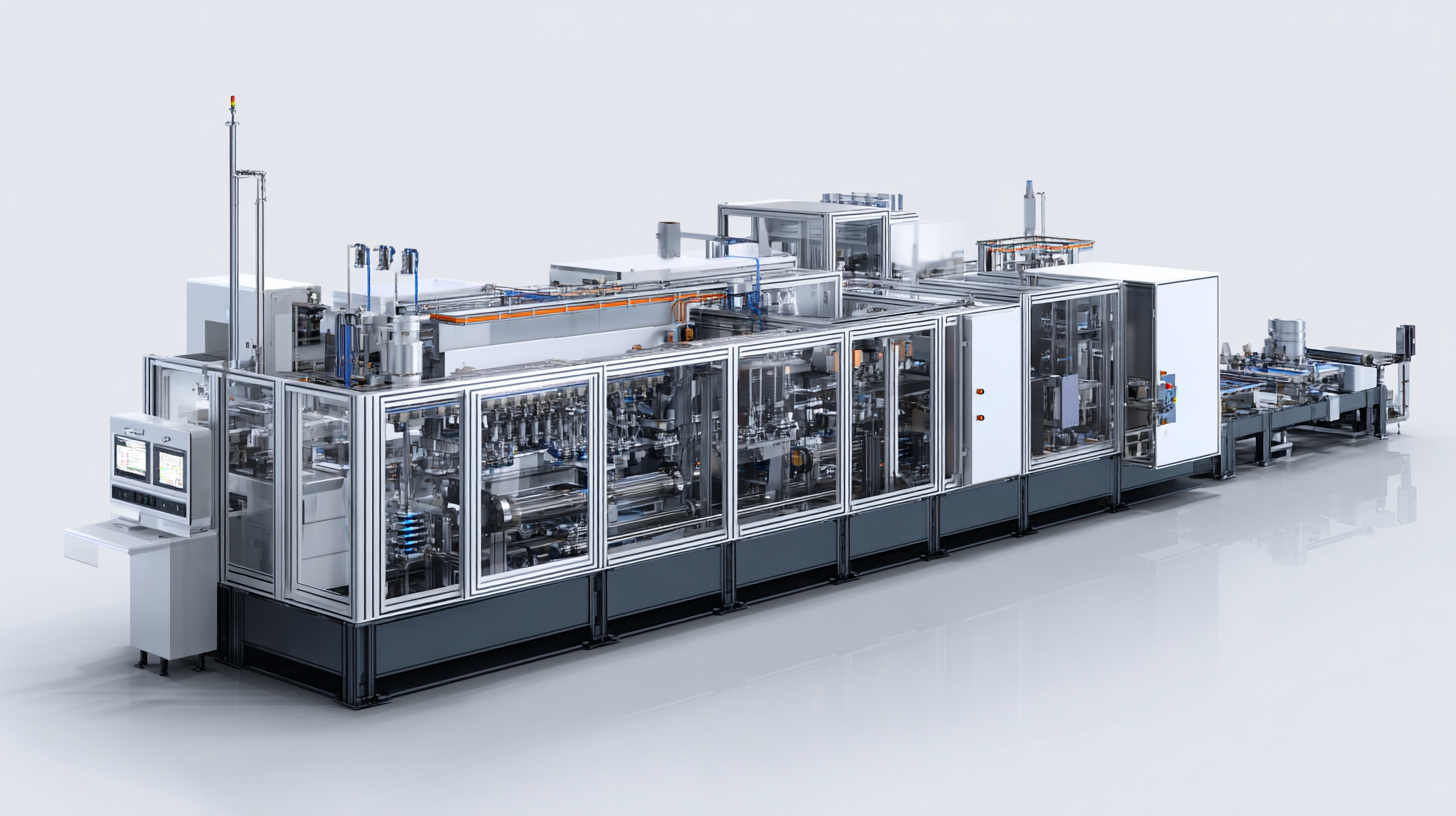

The Role of Automation and AI in Enhancing Thermal Break Machine Efficiency

As industries strive for greater efficiency, the integration of automation and artificial intelligence (AI) in thermal break machines is becoming increasingly significant. Reports suggest that by 2025, the global market for automated thermal break machines is projected to grow by approximately 22%, driven largely by advancements in AI technology. Automation not only reduces production times but also enhances precision and reduces waste in the manufacturing processes. Smart sensors and machine learning algorithms allow these machines to adapt to varying materials and production demands, enabling manufacturers to optimize output while maintaining high quality.

AI's role in predictive maintenance is particularly noteworthy. According to a recent study, companies employing AI-driven maintenance solutions can see downtime reduced by up to 30%. This translates to significant cost savings and improved operational efficiency. By using data collected from thermal break machines, AI algorithms can predict failures before they occur, allowing for timely interventions without halting production. As the industry moves towards more sustainable manufacturing practices, the efficiency gains made possible through automation and AI will not only enhance productivity but also contribute to environmental conservation efforts by minimizing excess consumption and waste.

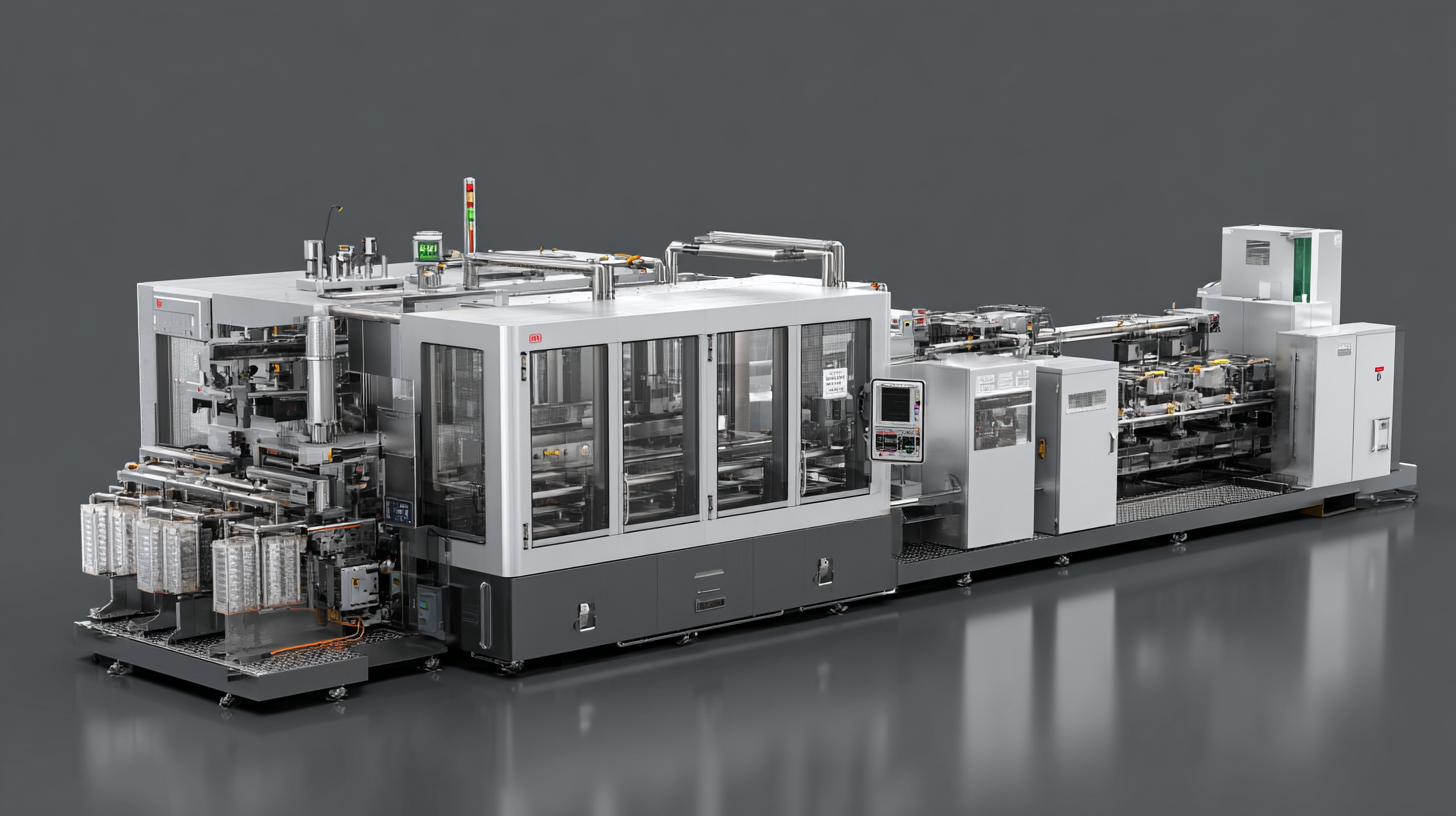

China's Competitive Edge: Strategies for Thriving in the Global Thermal Break Market

As we approach 2025, China's strategies for dominating the global thermal break market reflect its broader ambition to become a leader in various industries. The "Made in China 2025" initiative aims to propel Chinese companies to the forefront of ten core industries, amplifying their innovative capacities and technological prowess. This vision is underpinned by significant investments in infrastructure and technology, particularly through the Belt and Road Initiative, which seeks to enhance global trade connections and economic growth across Asia and beyond.

Amid this evolution, China's approach to manufacturing thermal break machines demonstrates its competitive edge. Chinese manufacturers are leveraging advanced production techniques and cost efficiencies to enhance their offerings in the thermal break market. By focusing on innovation and sustainability, these companies are not only improving product quality but also positioning themselves as key players in the international arena. This strategy, combined with their swift adaptation to technological changes, could allow China to outpace other competitors, making the global landscape increasingly reliant on Chinese expertise in thermal break technology.