The Future of Energy Efficient Windows with Advanced Window Making Machine Technology

As the global demand for energy efficiency continues to surge, driven by increasing environmental concerns and legislative measures, the window manufacturing industry is on the brink of transformation. A recent report from the U.S. Department of Energy highlights that energy-efficient windows can reduce energy bills by up to 30%, underscoring their critical role in sustainable building practices.

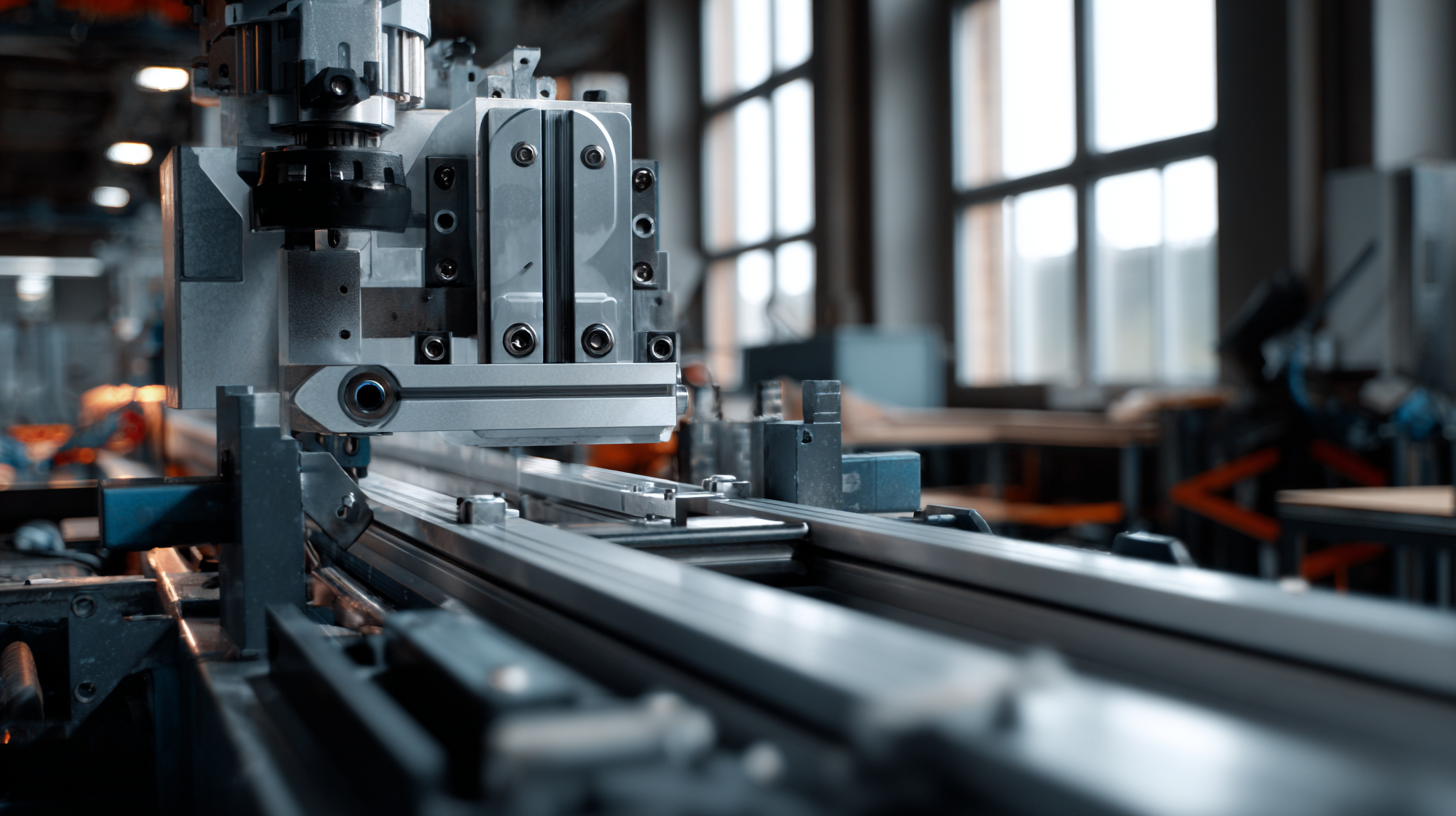

This shift is being facilitated by advancements in technology, particularly through the use of innovative Window Making Machines. These machines not only enhance production efficiency but also improve the precision and quality of window products, allowing manufacturers to meet stringent energy codes and standards. As industries adapt to meet the rising expectations for sustainable construction, the integration of advanced Window Making Machine technology stands as a pivotal factor in shaping the future of energy-efficient windows.

The Impact of Advanced Window Making Technology on Energy Efficiency Standards

The advent of advanced window making technology is poised to significantly impact energy efficiency standards in the construction industry. These innovative manufacturing methods enable the production of windows that effectively minimize heat loss, thus reducing energy consumption in buildings. By employing high-performance materials and precision engineering, manufacturers can create windows that surpass traditional specifications, allowing for better insulation and increased natural light. This shift not only promotes a sustainable future but also aligns with global efforts to reduce carbon footprints.

Tips for selecting energy-efficient windows include considering the window's U-factor, which measures heat transfer, and the Solar Heat Gain Coefficient (SHGC), which indicates how much solar radiation passes through the window. Look for windows that come with Energy Star ratings, as these products meet strict efficiency guidelines set by the U.S. Environmental Protection Agency. Additionally, opt for double or triple glazing, which further enhances insulation and contributes to overall energy savings.

As energy efficiency standards evolve, the integration of advanced technologies will play a crucial role in the modernization of window manufacturing. Embracing these innovations will not only improve the performance of buildings but will also foster a market that prioritizes sustainability. The shift toward more stringent energy efficiency standards will encourage stakeholders to invest in cutting-edge window technologies, ensuring a greener future for the built environment.

Key Innovations in Window Manufacturing Machines for Sustainable Development

The advancements in window manufacturing machines are pivotal for promoting sustainable development and enhancing energy efficiency. According to the Global Window Industry report, energy-efficient windows can reduce heating and cooling costs by up to 30%, emphasizing the urgent need for innovation in production processes. Automated technologies in window manufacturing, such as state-of-the-art cutting, sealing, and insulating machines, are evolving to minimize waste and improve material utilization. With precision engineering, these machines can produce window units that meet stringent energy performance standards, particularly as regulations become more stringent globally.

Key innovations in window-making technology include the integration of smart manufacturing techniques and advanced materials. Reports indicate that the use of low-emissivity (Low-E) coatings in window production results in a 50% reduction in energy consumption compared to traditional windows. Furthermore, the introduction of IoT systems in production allows for real-time monitoring and adjustments, ensuring optimal efficiency. As manufacturers adopt these advanced techniques, they not only enhance the quality and performance of their products but also contribute to a significant reduction in the carbon footprint of the construction industry, aligning with global sustainability goals.

The Future of Energy Efficient Windows

The Role of Energy Efficient Windows in Reducing Carbon Footprint: Statistics and Trends

The transition towards energy-efficient windows has gained momentum as a crucial strategy in reducing carbon footprints. According to the U.S. Department of Energy, windows account for 25-30% of residential heating and cooling energy use. This statistic underscores the need for advanced window technologies that reduce energy loss, thus playing a significant role in climate change mitigation efforts.

Recent trends indicate that the market for energy-efficient windows is projected to grow significantly. The Global Market Insights report suggests that the energy-efficient windows market could exceed $500 billion by 2025, primarily driven by increasing awareness of energy conservation and sustainability. Moreover, studies reveal that upgrading to energy-efficient windows can reduce household energy consumption by up to 15%, leading to substantial reductions in greenhouse gas emissions over time. Not only do these windows help homeowners save on energy bills, but they also contribute to a larger environmental goal of lowering overall carbon emissions as part of the global effort to combat climate change.

Comparative Analysis of Traditional vs. Advanced Window Production Methods

The production of energy-efficient windows is undergoing a significant transformation, driven by advancements in window making machine technology. Traditional window production methods often rely on manual labor and outdated machinery, which can lead to inconsistencies in quality and energy performance. Bulk manufacturing processes typically result in higher waste and lower customization options, hindering the ability to cater to specific energy efficiency standards.

In contrast, advanced window production methods utilize cutting-edge machinery that automates processes with precision and efficiency. These machines can integrate advanced materials and coatings designed to enhance insulation and reduce energy loss. The use of computer-aided design (CAD) and manufacturing (CAM) technologies enables manufacturers to produce windows with exact specifications, improving not only the energy efficiency but also the aesthetic appeal.

Additionally, these modern methods often incorporate sustainability measures, such as reduced waste and energy consumption during production, making them more environmentally friendly. As the demand for energy-efficient solutions grows, the shift towards advanced technologies is set to redefine the window manufacturing industry.

Future Market Predictions for Energy Efficient Windows: Insights and Data

The energy-efficient windows market is poised for significant growth in the coming years. As global trends shift towards sustainable living, the demand for advanced window technologies is also increasing. Predictions indicate that the market for energy-efficient windows will be influenced by innovations in window-making machinery, enhancing insulation and reducing energy costs for homeowners and businesses alike. By 2032, the implications of these advancements could lead to substantial increases in adoption rates, reflecting in both residential and commercial sectors.

Tips: When considering energy-efficient windows for your property, look for options that have high thermal performance ratings. Additionally, exploring local incentives for energy-efficient home upgrades can provide financial benefits.

The interplay between the energy-efficient windows market and the broader HVAC industry cannot be overlooked. With the global air conditioning market projected to grow from $137.37 billion in 2025 to $211.9 billion by 2032, integrating efficient window solutions can significantly impact energy consumption. This alignment underscores the importance of making informed choices about both windows and lighting in creating a more sustainable and cost-effective living environment.

Tips: Invest in smart window technology that allows for automatic tinting to control heat and light levels effectively. This innovation not only enhances comfort but can also lead to lower energy bills over time.

The Future of Energy Efficient Windows with Advanced Window Making Machine Technology

| Year | Market Size (Million USD) | Growth Rate (%) | Key Technology Trends |

|---|---|---|---|

| 2023 | 8500 | 5.2 | Low-E Coatings, Smart Glazing |

| 2024 | 8950 | 5.4 | Insulating Glass Technology, UV Filtering |

| 2025 | 9400 | 5.6 | Dynamic Glazing, Energy Harvesting |

| 2026 | 9900 | 5.8 | Nanotechnology, Self-Cleaning Glass |

| 2027 | 10500 | 6.0 | Integrated IoT, Advanced Insulation |

Related Posts

-

Excellence in Quality Chinese Window Manufacturing Machines for Global Markets

-

Discover the Innovations in Window Making Equipment Transforming the Industry

-

Discover Innovative Aluminium Door Machines at the Record Breaking 137th Canton Fair

-

Unlocking Efficiency in Aluminium Window Manufacturing with Advanced Fabrication Machines

-

7 Essential Insights for Sourcing Aluminium Door Making Machines Globally

-

Exploring Various Types of Best Aluminium Machinery for Your Manufacturing Needs