How to Choose the Right Stainless Steel Wire Mesh for Your Needs

Choosing the right stainless steel wire mesh is crucial for various applications. The market for stainless steel wire mesh has been continuously growing. According to a recent industry report, it is projected to reach $2.5 billion by 2025, reflecting an increasing demand in sectors like construction and filtration.

Industry expert Dr. Emily Chen emphasizes, "Selecting the appropriate stainless steel wire mesh can significantly impact product quality." This statement highlights the importance of making informed choices. Different types of stainless steel wire mesh serve varied purposes. Misunderstanding these needs can lead to costly mistakes and performance issues.

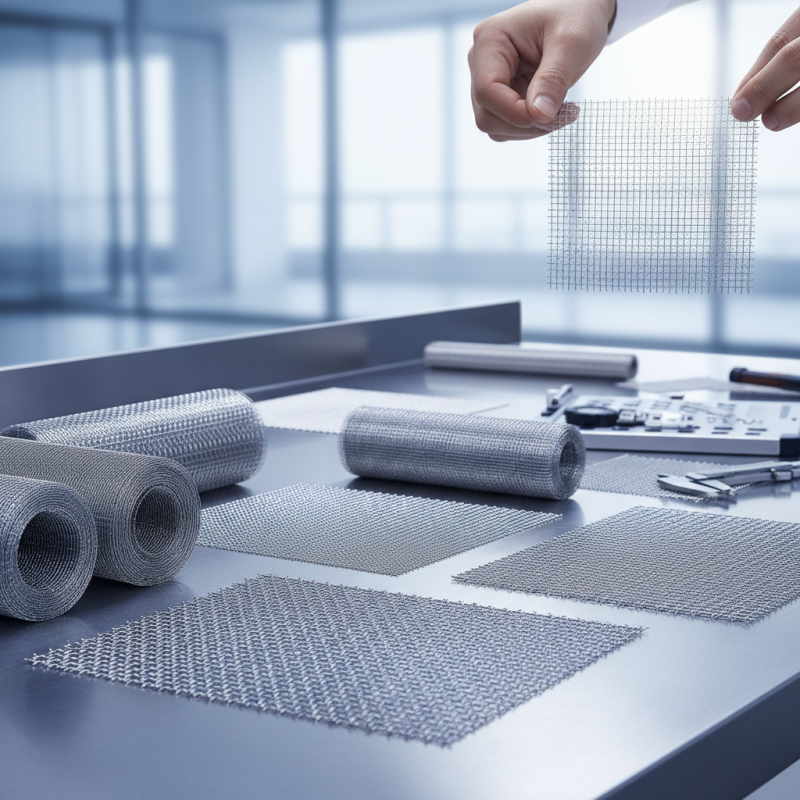

Reflecting on your specific requirements is essential. Consider factors such as the mesh size, material grade, and intended application. The challenges of finding the perfect fit can be daunting. Learn from industry experiences to make better decisions in selecting stainless steel wire mesh.

Understanding Stainless Steel Wire Mesh: Types and Materials

When selecting the right stainless steel wire mesh, understanding its types and materials is essential. Stainless steel wire mesh comes in various grades, each suitable for specific applications. The most common grades are 304 and 316. Grade 304 is widely used in general applications due to its corrosion resistance and affordability. However, it may not withstand harsh environments. In contrast, 316 offers better resistance to saltwater and acidic conditions. It’s crucial to evaluate the environment in which the mesh will be used.

Apart from the grades, the weave pattern plays a vital role. Common patterns include plain weave, twilled weave, and Dutch weave. Plain weave is simple and cost-effective, suitable for basic filtration needs. Twilled weave is stronger and more flexible, ideal for more demanding applications. Dutch weave combines tightly woven wires to provide excellent filtration, but it may be less versatile. Each type has specific strengths and weaknesses.

Some buyers overlook the importance of wire diameter and opening size. Thicker wires provide strength, but larger openings affect filtration capability. Finding the right balance between strength and functionality can be challenging. Moreover, the choice often depends on personal preferences. Careful consideration of these factors can lead to better decision-making and long-term satisfaction.

Types of Stainless Steel Wire Mesh and Their Applications

Assessing Your Project Needs: Size, Mesh Count, and Opening

When selecting stainless steel wire mesh, assessing your project needs is crucial. Start with size. Measure the exact dimensions required for your application. An oversized mesh can create issues, while an undersized one might not perform as intended. Think about the area you need to cover. For smaller applications, a compact size works well. Larger spaces may require more robust options.

Mesh count is another essential factor. It refers to how many openings occur in a linear inch. Higher mesh counts lead to finer openings. This is useful for filtering or containment. However, too fine a mesh may cause airflow restrictions. Evaluate the purpose carefully. If it is for support, a lower mesh count could be more suitable.

Don't overlook the importance of opening size. The diameter of the wire affects the overall rigidity. It can also influence the material's weight. In some cases, a heavier, sturdier option is necessary. But this could add costs. Balancing weight and strength requires consideration. Small changes can lead to unexpected challenges down the line. Always analyze your specific needs to make the best choice.

Evaluating Corrosion Resistance and Other Performance Factors

When selecting stainless steel wire mesh, corrosion resistance is critical. Different grades of stainless steel offer varying levels of protection against rust and degradation. For instance, 304-grade stainless steel exhibits moderate corrosion resistance but may falter in highly acidic environments. A report by the International Stainless Steel Forum highlights that 316-grade stainless steel is often preferred for marine applications due to its superior corrosion resistance. This higher nickel and molybdenum content enhances its durability.

The wire mesh's performance also hinges on its surface finish. A smoother surface reduces the likelihood of pitting and staining. Studies show that mesh with a polished finish can have a significantly lower corrosion rate, which is essential in food processing and chemical industries. Chemical exposure can accelerate wear, leading to potential failures.

Evaluating your specific environment and usage is vital. Regular assessments are necessary, especially in extreme conditions. Neglecting this can lead to unexpected costs and safety issues. Selecting the right type requires careful consideration to ensure longevity and effectiveness in your application.

Selecting the Right Wire Diameter and Weave Pattern

When selecting stainless steel wire mesh, wire diameter and weave pattern are critical factors. The wire diameter affects the mesh's strength and the size of openings. Thicker wires provide more durability but also heavier weight. If strength is your priority, opt for thicker wires, but remember, they can restrict airflow and light.

The weave pattern impacts the mesh's appearance and functionality. A plain weave offers uniform openings, making it ideal for filtration and separation applications. A twill weave provides more flexibility and a tighter grip on materials, but it may not perform well for fine filtration. Visualizing how materials will interact with the mesh can clarify your decision.

Tips: Consider the environment where the mesh will be used. Will it be exposed to harsh chemicals or extreme temperatures? Additionally, always assess your needs against the mesh's properties. Mismatched selections can lead to poor performance or premature wear. Pay attention to details; even minor variations in wire diameter can yield different outcomes. Make sure to think through every aspect before making your final choice.

How to Choose the Right Stainless Steel Wire Mesh for Your Needs

| Wire Diameter (mm) | Mesh Opening (mm) | Weave Pattern | Applications |

|---|---|---|---|

| 1.0 | 1.0 | Plain Weave | Filtration, Food Processing |

| 1.5 | 2.0 | Twill Weave | Chemical Processing, Aerospace |

| 2.0 | 3.0 | Dutch Weave | Oil Filtration, Water Treatment |

| 3.0 | 4.0 | Reverse Dutch Weave | Pharmaceutical, Filtration |

| 4.0 | 5.0 | Lock Crimp Weave | Mining, Heavy Duty Filtration |

Ensuring Compliance with Industry Standards and Regulations

When selecting stainless steel wire mesh, industry standards are critical. They guide material choice and manufacturing processes. Understanding these regulations ensures that your mesh meets specific performance criteria. Compliance often varies between sectors. It’s necessary to research the standards relevant to your industry.

For example, food processing and medical applications require strict hygiene and safety standards. Your wire mesh must resist corrosion and withstand high temperatures. However, not all products claim compliance. Some may look compliant but don't perform well under scrutiny. Always ask for documentation. Be critical of certifications you receive.

Choosing the right wire mesh involves careful consideration of these factors. Regular audits of suppliers can help ensure ongoing compliance. It’s not just a one-time checklist; it’s an ongoing commitment. Reflect on your choices and the standards you meet. Your decision affects quality and performance in the long run.