How to Choose the Right Lamination Machine for Your Needs?

Choosing the right Lamination Machine can significantly impact your business operations. In the industry, lamination machines have evolved, offering diverse features tailored to specific needs. According to a recent report by Smith & Associates, the global lamination machine market is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2028. This growth reflects an increasing demand for lamination in packaging and document protection.

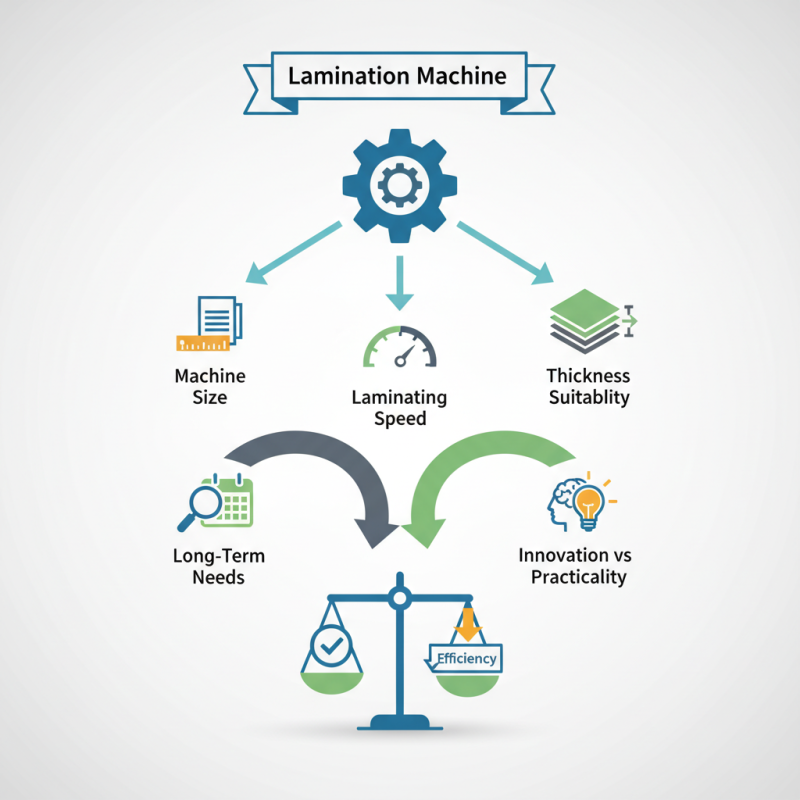

Expert John Doe, a leading figure in the lamination technology sector, emphasizes, "Selecting a suitable lamination machine is crucial for efficiency." As businesses expand, the choice of a lamination machine often presents challenges. With numerous options, it is essential to consider aspects like machine size, laminating speed, and thickness suitability.

Moreover, the importance of assessing long-term needs cannot be overstated. While one might feel tempted by advanced technology, it is vital to reflect on actual requirements. Businesses frequently misjudge their usage needs, leading to underutilization or overinvestment in equipment. Ensuring the right fit for your lamination needs means balancing innovation with practicality.

Understanding Different Types of Lamination Machines Available

Lamination machines come in various types, each tailored to specific tasks. Some machines are designed for basic document lamination while others cater to more complex projects like encapsulation or pouch lamination. According to industry data, the global laminating machine market was valued at approximately $1.1 billion in 2022 and is projected to grow steadily due to increased demand in sectors like education and hospitality.

The choices include thermal and cold laminators. Thermal laminators use heat to seal the lamination film to the material. They are fast and efficient, ideal for frequent use. Cold laminators, on the other hand, operate without heat, making them suitable for heat-sensitive materials. A report by Smithers Pira indicates that thermal laminators account for over 60% of the market share, reflecting their widespread popularity.

Selecting the right machine can be challenging. Users often overlook maintenance costs and ease of operation. A frequent mistake is choosing a machine based solely on initial price. It’s essential to consider long-term efficiency and the types of materials regularly processed. Understanding these factors can prevent costly missteps in the lamination process.

Key Features to Consider When Selecting a Lamination Machine

Choosing the right lamination machine can be challenging. Several key features should guide your decision. For instance, think about the size of the documents you will laminate. A machine that handles larger formats may be more versatile. Consider your workspace too. A compact model might fit better in a small office.

Another important aspect is the laminating speed. Faster machines can save you time, especially during bulk jobs. However, speed might come at the expense of quality. You may need to find a balance that works for you. Film thickness is another detail to ponder. Thicker films offer better protection, but they also require a compatible machine.

Don't overlook usability. A machine should have intuitive controls. Features like adjustable temperature settings can enhance the laminating process. Keep an eye out for models with safety features, too. Finally, consider your budget. Higher prices don't always guarantee better quality. Reflecting on your true needs can help you avoid overspending.

Key Features Considered in Choosing a Lamination Machine

Assessing Your Laminating Volume and Project Needs

When it comes to selecting a lamination machine, understanding your project needs is crucial. How many items do you plan to laminate? If it’s just a few, a compact model might work. For larger projects, a high-capacity machine will save you time. Consider the thickness of the materials you will use; some machines handle thicker items better than others.

Think about the types of lamination you’ll undertake. Will you need cold or hot lamination? Each method affects the finish and durability differently. It’s also wise to assess the ease of use. Some machines feature complex settings that might overwhelm beginners. Reflect on how often you'll use the machine. If you laminate sporadically, investing in a high-end model could feel excessive.

Don't overlook the maintenance aspect. Regular upkeep ensures longer machine life but requires effort. User feedback can provide insights, yet individual experiences vary. Thus, take reviews with caution. Sometimes, what works for one project may not suit another. Identifying these factors helps you find a machine that aligns with your actual needs.

Evaluating Budget Constraints and Cost-Effectiveness

When evaluating your budget for a lamination machine, think carefully about both upfront costs and operational expenses. While some machines might seem cheaper initially, they can lead to higher costs over time. For instance, low-quality laminators might require frequent repairs or replacement materials. These hidden costs can drain your budget.

Consider the volume of work you'll handle. If you only need a lamination machine for occasional tasks, investing heavily may not make sense. A mid-range model could suit your needs without breaking the bank. On the other hand, higher volume users often benefit from investing in robust machines. They may save money with bulk supplies and less downtime.

Don't overlook the importance of efficiency. A machine that operates slowly may cost less initially but can waste time and labor. If you often find yourself waiting, think again. The extra cost for a faster model might be worth it. Evaluate your needs and potential growth too. Reflect on what you truly need before you buy.

Reading Reviews and Seeking Recommendations for Best Options

When selecting a lamination machine, reading reviews is crucial. Many online platforms provide user insights. These insights can reveal strengths and weaknesses. Look for common themes in the reviews. This will help narrow down your choices. A visually appealing machine might not perform well. Users may praise performance but criticize durability.

Seeking recommendations can enhance your decision. Talk to colleagues or friends who have experience. They might suggest machines that suit your needs. Personal experiences often highlight details you may overlook. Some might mention noise levels or heat settings. These aspects can greatly impact usability.

Don’t ignore negative feedback. It's essential to weigh both pros and cons. A five-star rating doesn’t guarantee satisfaction. Reflect on your priorities. Are you focusing on speed, size, or versatility? Knowing what you deem essential will drive better choices. Remember, no machine is perfect. Each has its quirks that may require adjustment.