How to Choose the Right Injection Machine Robot for Your Needs?

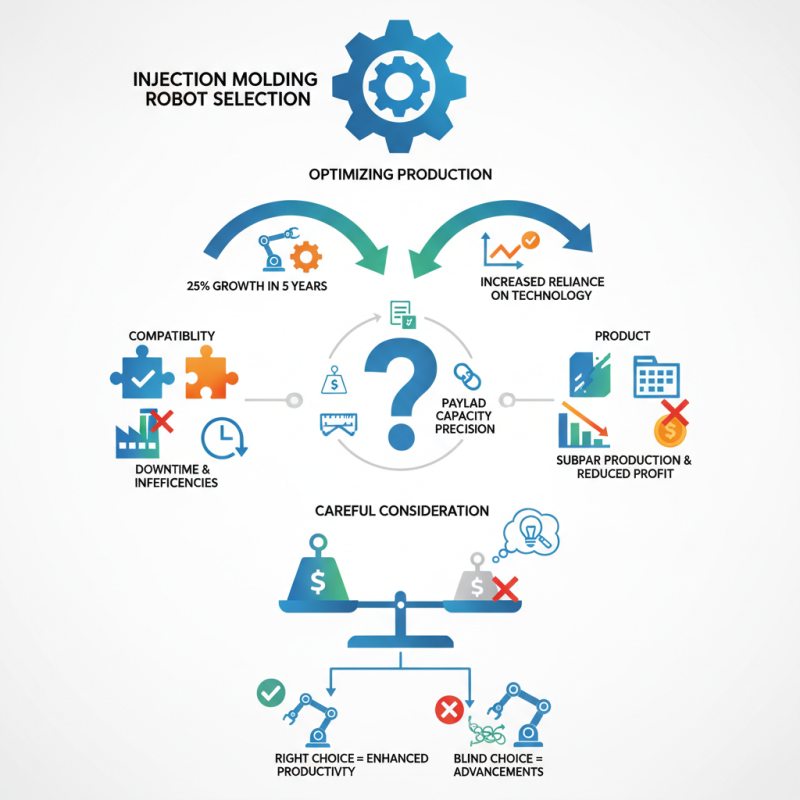

Choosing the right Injection Machine Robot is crucial for optimizing production efficiency. According to a recent industry report, the use of robotic automation in injection molding has surged by approximately 25% in the last five years. This growth highlights the increasing reliance on technology in manufacturing processes. However, many businesses struggle to identify the right model for their specific needs.

One common mistake is overlooking the importance of compatibility. An Injection Machine Robot must seamlessly integrate with existing machinery. Inadequate evaluations can lead to costly downtime and inefficiencies. Furthermore, improper selection may result in subpar production outcomes, creating a ripple effect on overall profitability.

Thoughtful consideration of factors such as payload capacity and precision requirements is essential. Each manufacturing environment has unique demands. In some cases, the cheapest option may not deliver the best value. Hence, it's necessary to reflect deeply before making a decision. Ultimately, the right Injection Machine Robot can enhance productivity, but blind choices can hinder potential advancements.

Understanding the Basics of Injection Molding Robots

Injection molding robots are crucial in modern manufacturing. They enhance precision and efficiency. Understanding their basics helps in making better choices.

These robots automate various tasks in the injection molding process. They can handle loading, unloading, and even sorting parts. Features vary widely among different models. Some focus on speed, while others prioritize precision. It’s essential to identify your specific needs. Will your operations benefit from a faster cycle, or is accuracy more critical?

Consider the workspace too. The size and layout of your facility can influence robot selection. A compact machine might suit smaller spaces, while larger operations can accommodate bigger options. Some users overlook the complexity of programming. Investing time in understanding the robot's programming can lead to greater efficiency.

Balancing these aspects can be challenging, yet essential for optimal performance.

Identifying Your Specific Automation Needs in Injection Molding

When selecting an injection machine robot, understanding your specific automation needs is crucial. According to a report by Grand View Research, the global injection molding market is expected to reach $364.9 billion by 2027. This growth highlights the importance of tailored automation solutions. Identify the type of materials you use. Some robots perform better with various thermoplastics while others excel with thermosets.

Tips: Assess the speed of production you aim for. Faster production can increase output but may require more sophisticated machinery. Think about your space. A compact robot may fit better into smaller facilities without compromising effectiveness.

Consider cycle times carefully. They influence everything from throughput to energy consumption. A robot with a shorter cycle time can lead to significant savings. However, more complexity might arise in programming and maintenance. Don't overlook these aspects. Reflect on how ease of integration with existing systems can affect production. Your automation needs are unique, and addressing them accurately can drive your success in injection molding.

Key Features to Consider When Choosing an Injection Machine Robot

When selecting an injection machine robot, certain key features demand your attention. Precision control is crucial. Research indicates that up to 80% of manufacturing defects stem from inadequate automation. A robot with high-precision features can significantly reduce these risks. Look for models that offer repeatability within ±0.1 mm. This can improve product quality dramatically.

Speed and efficiency also matter. An injection machine robot should maximize output while minimizing cycle time. Data shows that faster robots can boost production efficiency by up to 30%. However, balancing speed with precision is essential. A very fast robot might sacrifice accuracy, leading to more defects and waste. Be mindful of this trade-off.

Lastly, adaptability is a vital feature. The ability to handle various injection molds and perform different tasks increases a robot's utility. Industry reports suggest that flexible automation is becoming a standard requirement. Robots that can quickly switch between tasks save time and reduce downtime. This capability is key for companies looking to remain competitive in a rapidly evolving market.

How to Choose the Right Injection Machine Robot for Your Needs? - Key Features to Consider When Choosing an Injection Machine Robot

| Feature | Description | Importance | Considerations |

|---|---|---|---|

| Payload Capacity | Maximum weight the robot can handle. | High | Ensure it meets the needs of your heaviest molds. |

| Speed | How quickly the robot can execute tasks. | Medium | Consider cycle times for your processes. |

| Precision | Ability to accurately position and manipulate items. | High | Essential for intricate mold designs. |

| Ease of Programming | How user-friendly the programming interface is. | Medium | Look for intuitive software and training options. |

| Compatibility | Works with existing machinery and systems. | High | Ensure it integrates seamlessly with your setup. |

| Maintenance | Level of maintenance and service required. | Medium | Check the ease and cost of maintenance procedures. |

Evaluating Cost vs. Performance in Injection Molding Robotics

When selecting an injection machine robot, cost and performance are key considerations. An effective balance can optimize production. Think about your budget. Entry-level robots may seem attractive, but they often compromise on quality and speed. Evaluate what you need from a robotic system. High performance typically comes with a higher price tag.

Look deeper into performance metrics. Speed, precision, and durability matter. A higher-priced robot may provide better cycle times, which directly affects productivity. On the flip side, a less expensive robot may struggle in high-demand settings. Maintenance costs also play a role. Sometimes, cheaper options incur more downtime.

Consider the specific applications you require. Not every robot fits every task. For example, some tasks require delicate handling, while others focus on speed. It's essential to assess your workflow and product requirements. Reflect on past experiences too. Did a previous robot meet your needs? Were limitations apparent? Assessing these experiences can guide the decision-making process, ensuring the next choice is more aligned with your requirements.

Future Trends in Injection Molding Robotics and Their Implications

The future of injection molding robotics is bright, with emerging trends shaping their role in manufacturing. Automation will continue to evolve, allowing for increased efficiency and precision. Advancements in AI and machine learning will enhance robotic capabilities. These technologies enable robots to learn from past operations, optimizing processes with minimal human intervention.

Tips: Consider the specific needs of your operation. Assess the volume and complexity of your projects. This analysis will guide you in selecting features that matter most. Don't underestimate the importance of flexibility. Robots that can adapt to different tasks can save costs in the long run.

As robotics become more sophisticated, collaboration between human workers and machines will grow. Human oversight remains essential, especially in complex tasks. It's crucial to rethink team dynamics as you integrate robotics. Determine areas where robots can complement the workforce, rather than replace it. Balancing human and robotic collaboration will lead to innovation and productivity.