How to Choose the Best Aluminium Window Machine for Your Business?

Choosing the right Aluminium Window Machine for your business is crucial. This decision impacts efficiency, quality, and profitability. With many options available, it can be overwhelming.

Consider your production needs first. Are you focusing on volume or customization? Each requirement demands different machine features. A high-capacity machine offers speed, while a versatile one allows flexible designs. If you choose incorrectly, it could hurt your bottom line. Many businesses overlook this before purchasing.

Evaluate the machine's technology and ease of use. Complex machinery may require extensive training, causing delays in production. Simpler models may lack advanced features but are user-friendly. This balance is essential for maximizing operational efficiency. Select wisely, as an Aluminium Window Machine is a long-term investment. The right choice can boost your business and future-proof your operations.

Understanding the Different Types of Aluminium Window Machines

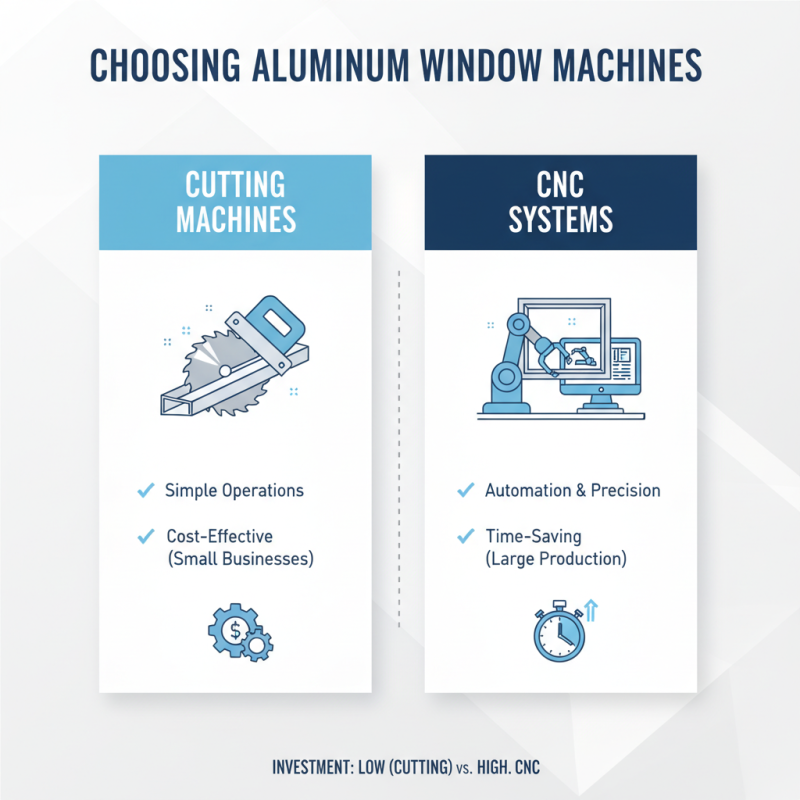

When choosing the right aluminium window machine, understanding the different types is crucial. The options range from simple cutting machines to complex CNC systems. Cutting machines are ideal for basic operations. They are user-friendly and cost-effective for small businesses. On the other hand, CNC machines offer automation and precision for larger production runs. They save time but require more initial investment.

Tips: Assess your production needs. Consider the volume and design complexity. This helps determine which type suits your business best. Also, think about future growth. A machine that meets your current needs may not suffice later.

Another factor to consider is the machine's maintenance requirements. Some machines need regular servicing, while others are low-maintenance. It's essential to understand the potential costs involved. Look for machines with good support and spare parts availability. This can save you time and frustration in the long run. Be aware of your skills as well. You may need training for advanced machines. Evaluate your team's capabilities and be realistic.

Assessing Your Business Needs for Aluminium Window Production

When assessing your business needs for aluminium window production, clarity is key. Understand your production volume. Are you a startup or an established business? This will influence the type of aluminium window machine you'll require. Evaluate the sizes and styles of windows you intend to produce. Ensure your equipment can handle a variety of profiles.

Tips: Consider your workflow. A machine that integrates seamlessly with your current processes is vital. Think about space requirements too. You need enough room not only for the machine but also for materials and finished products.

Don’t overlook automation features. Automated functions can enhance efficiency and reduce labor costs. However, keep in mind that higher technology may lead to more maintenance issues. Reflect on your workforce's skill level. Can they operate complex machinery, or do they require simpler systems? Always assess the potential for future upgrades.

Tips: Never rush into a decision based on price alone. Quality and efficiency are essential for long-term success. Ensure the machine you choose aligns with your business strategy.

How to Choose the Best Aluminium Window Machine for Your Business? - Assessing Your Business Needs for Aluminium Window Production

| Criteria | Description | Importance (1-5) | Considerations |

|---|---|---|---|

| Production Capacity | The amount of aluminium windows produced in a given time frame. | 5 | Match with project demands. |

| Machine Type | Different machines for cutting, welding, and assembling. | 4 | Evaluate your specific production process. |

| Ease of Use | User-friendly interface for operators. | 3 | Consider training needs for staff. |

| Maintenance Requirements | Frequency and cost of maintenance of the machine. | 4 | Assess availability of service providers. |

| Budget | Total cost of acquisition including installation and training. | 5 | Balance between quality and cost. |

| Technology Features | Innovative features like automation and AI integration. | 4 | Future-proofing your production line. |

Key Features to Look for in Aluminium Window Machines

When selecting an aluminium window machine, key features play a crucial role. Efficiency is paramount. Look for machines that offer high-speed production without compromising quality. Consider the power consumption of the model. Machines that use less energy can save costs in the long run.

Precision is another vital aspect. Accurate measurements ensure that windows fit perfectly, reducing waste and rework. Adjustable settings are essential for handling various sizes and designs. This flexibility boosts productivity. Additionally, durability matters. Machines should withstand daily wear and provide consistent output over time.

Ease of use cannot be overlooked. A user-friendly interface allows operators to work efficiently. Training time can be significantly reduced with intuitive controls. However, this doesn't mean that the setup is always perfect. Troubleshooting common issues may require patience and experience. Investing in a reliable support system can help with those challenges. Ultimately, it’s about finding the right balance of these features to enhance your production line.

Evaluating the Cost vs. Benefits of Aluminium Window Equipment

When choosing aluminium window machinery, cost versus benefits is crucial. High-quality equipment ensures precision and durability, impacting your bottom line. However, initial investments can be steep. It’s important to balance these costs with expected returns.

Tips: Look for machines that offer energy efficiency. They can lower long-term operational costs. Also, consider the machine's maintenance requirements. Frequent repairs can eat into your profits. Analyze how often you’ll need to upgrade. Reassess your needs regularly.

Sometimes, the most expensive machine isn’t the best fit. Reflect on your production capacity and target market. A lower-cost option might suffice for smaller operations. Additionally, evaluate the warranty and support provided. This can save you money on unexpected failures. Prioritize equipment that meets your specific production needs while keeping your budget in check.

Researching Manufacturers and Suppliers of Aluminium Window Machines

When searching for aluminium window machines, it's crucial to evaluate manufacturers and suppliers thoroughly. Look for companies that have years of experience in the industry. Check their reputation online through reviews and testimonials. Engaging with other businesses can provide insights on their reliability and product quality.

Tips: Visit trade shows or workshops. Networking at these events can lead to valuable connections. You may find suppliers who offer good after-sales support. Also, consider local suppliers to reduce shipping costs and ensure quick service.

Don't overlook the importance of machine specifications. Different projects may require different features. Newer technology can be beneficial, but it might come with a steep learning curve. Take time to understand the machine's capabilities and limitations. Remember, an overly complex machine can lead to frustration if your team lacks proper training.

Related Posts

-

Unlocking Efficiency in Aluminium Window Manufacturing with Advanced Fabrication Machines

-

Exploring the Unique Features and Applications of Aluminium Door Window Manufacturing Equipment

-

Maximizing Efficiency: Optimizing Your Aluminium Door Window Manufacturing Process

-

Global Buyers Discover High-Quality Chinese Aluminum Window Machinery: A New Era of Manufacturing Excellence

-

Top Strategies for Sourcing the Best Aluminium Door Making Machine in Global Markets

-

7 Simple Tips to Choose the Most Effective Best Aluminium Door Machine