Exploring Various Types of Best Aluminium Machinery for Your Manufacturing Needs

The manufacturing industry has witnessed significant advancements in technology, and one critical area of innovation is in Aluminium Machinery. According to a report from Research and Markets, the global aluminium machinery market is expected to grow at a CAGR of 5.2% from 2021 to 2026, highlighting the increasing demand for efficient and high-quality machinery in the production process.

With the versatility and lightweight properties of aluminium, manufacturers are seeking specialized machinery that can streamline operations, enhance productivity, and reduce waste. This blog will explore various types of the best aluminium machinery available on the market today, providing insights into how these tools can meet diverse manufacturing needs while driving efficiency and sustainability in operations.

With the versatility and lightweight properties of aluminium, manufacturers are seeking specialized machinery that can streamline operations, enhance productivity, and reduce waste. This blog will explore various types of the best aluminium machinery available on the market today, providing insights into how these tools can meet diverse manufacturing needs while driving efficiency and sustainability in operations.

Understanding the Importance of Aluminium Machinery in Manufacturing

Aluminium machinery plays a crucial role in modern manufacturing, facilitating processes that enhance efficiency and product quality. According to a report by ResearchAndMarkets, the global aluminium extrusion market is projected to reach USD 55 billion by 2025, driven by the increasing demand for lightweight and durable materials in various industries, including automotive and construction. This surge in demand underscores the importance of investing in advanced aluminium machinery, which allows manufacturers to keep pace with evolving market needs.

Moreover, the adoption of automated aluminium processing solutions has been on the rise. A study published by Allied Market Research estimates that the global market for industrial automation in aluminium manufacturing will grow at a CAGR of 8.3% from 2021 to 2028. This growth reflects a growing recognition among manufacturers of the advantages of precision equipment and automated systems, such as reduced operational costs and enhanced production rates.

By integrating state-of-the-art aluminium machinery, manufacturers are not only improving their output but also ensuring a more sustainable approach to resource management, thereby aligning with industry trends towards eco-friendly production practices.

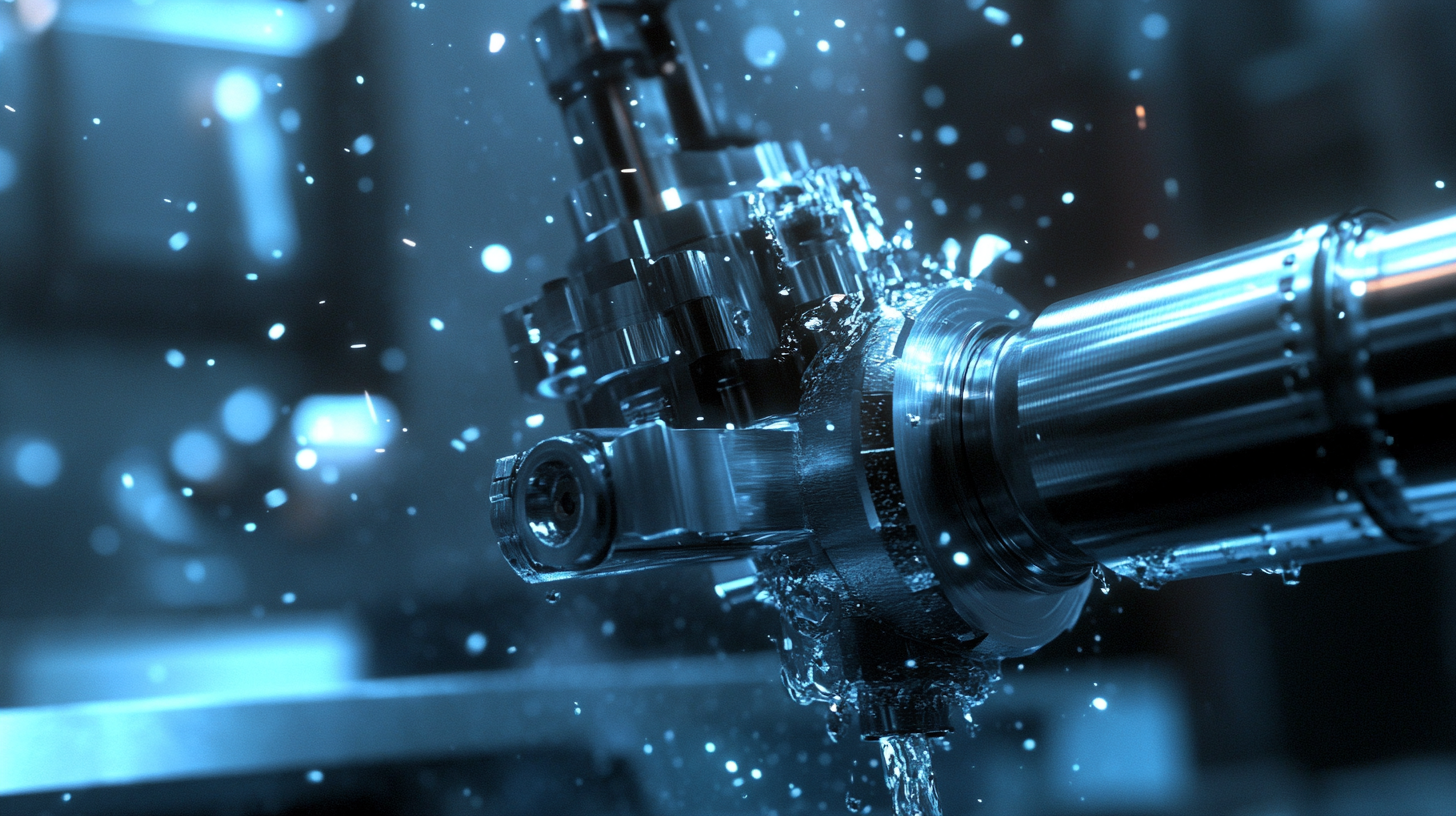

Types of Aluminium Machinery: A Comprehensive Overview for Manufacturers

When it comes to manufacturing, the choice of aluminium machinery can significantly impact efficiency and quality. Understanding the various types available is crucial for manufacturers seeking optimal performance. The primary categories of aluminium machinery include extrusion machines, die casting machines, and CNC machining centers. A recent industry report by Grand View Research noted that the global aluminium machinery market is expected to reach USD 33.4 billion by 2027, growing at a CAGR of 5.7%—highlighting the rising demand for advanced machinery solutions.

Tips for selecting the right aluminium machinery include evaluating the specific requirements of your production process. For instance, if high precision is critical, CNC machining centers are recommended due to their capability to perform intricate tasks with accuracy. For manufacturers focusing on bulk production of aluminium profiles, extrusion machines could be the best fit, considering their efficiency in mass production.

Additionally, it’s vital to assess the technology behind the machinery. Many modern machines come equipped with advanced automation and software controls, which can not only enhance productivity but also reduce waste. Investing in updated machinery that offers features like energy efficiency and user-friendly operation can lead to significant long-term savings and improved output quality.

Top 5 Factors to Consider When Choosing Aluminium Machinery for Your Needs

When choosing aluminium machinery for manufacturing needs, several key factors should be considered to ensure optimal performance and efficiency. First and foremost, the machinery's size and capacity must align with your production requirements. Assess the volume of aluminium you plan to work with and choose machinery that can handle that scale effectively. Overestimating needs can lead to unnecessary expenses, while underestimating can hinder productivity.

Another crucial factor is the technology and features of the machinery. Modern aluminium machinery often includes advanced automation and precision capabilities that can significantly enhance production efficiency and output quality. Evaluate technologies such as CNC controls, which allow for greater accuracy and flexibility in production processes. Additionally, consider the ease of maintenance and the availability of technical support. Reliable machinery can reduce downtime and keep production running smoothly, making it essential to select equipment from reputable manufacturers known for their customer service and support networks.

Top 5 Types of Aluminium Machinery for Manufacturing Needs

This chart represents the distribution of various types of aluminium machinery commonly used in manufacturing, showcasing their effectiveness based on efficiency, cost, and versatility.

Advantages of Investing in High-Quality Aluminium Machinery for Production Efficiency

Investing in high-quality aluminum machinery is crucial for enhancing production efficiency in the manufacturing sector. Advanced machinery not only improves the speed and precision of the production process but also significantly reduces waste and energy consumption. High-quality equipment often incorporates the latest technological advancements, ensuring that your manufacturing processes remain competitive and adaptable to market changes.

When considering the purchase of aluminum machinery, it's essential to evaluate the long-term benefits rather than just the upfront costs. Investing in durable, efficient machines can lead to lower maintenance costs and increased uptime, ultimately contributing to higher profit margins.

**Tips:** Always conduct thorough research on the machinery's specifications and performance records before making a decision. Additionally, consider partnering with reputable suppliers who can provide ongoing support and training for your workforce. This not only enhances operational efficiency but also ensures that your team is well-equipped to take full advantage of the machinery's capabilities.

Exploring Various Types of Best Aluminium Machinery for Your Manufacturing Needs

| Type of Machinery | Primary Use | Advantages | Production Efficiency Benefits | Estimated Cost (USD) |

|---|---|---|---|---|

| Aluminium Cutting Machine | Cutting aluminium profiles | Precision cutting, reduced waste | Increases speed and accuracy | $15,000 - $30,000 |

| Aluminium Extrusion Press | Forming aluminium shapes | High efficiency, versatile shapes | Maximizes output with minimal effort | $50,000 - $200,000 |

| Aluminium Welding Machine | Joining aluminium parts | Strong joints, reduced manual labor | Enhances speed of assembly | $20,000 - $40,000 |

| Aluminium CNC Machine | Precision machining of parts | High precision, automated operations | Consistent quality and reduced cycle times | $30,000 - $150,000 |

| Aluminium Anodizing Equipment | Surface treatment of aluminium | Improved corrosion resistance, aesthetic finishes | Enhances product durability and appeal | $25,000 - $100,000 |

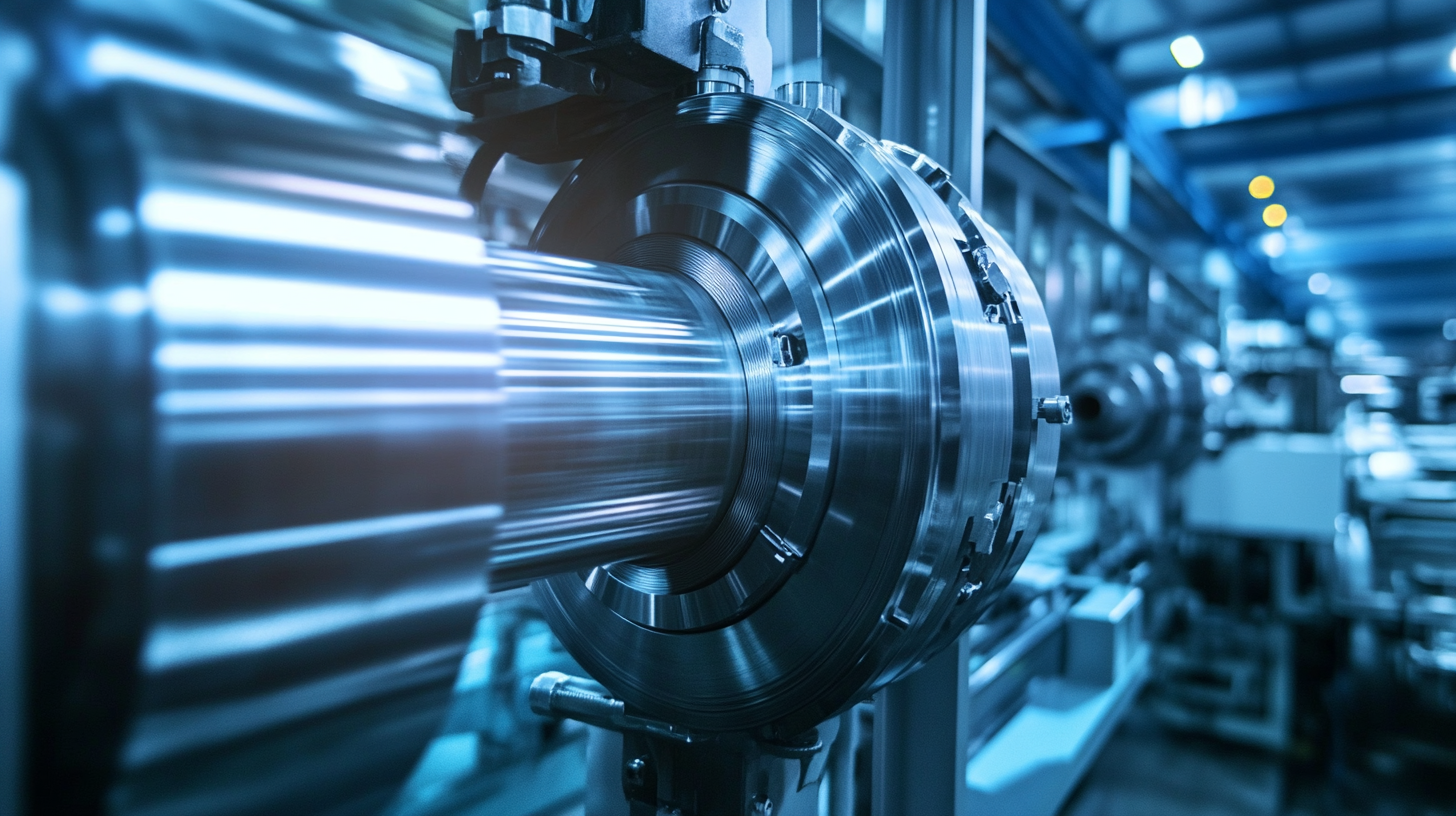

Innovations in Aluminium Machinery: What to Look for in Modern Manufacturing Solutions

In the ever-evolving landscape of manufacturing, innovations in aluminium machinery are crucial for staying competitive. Modern manufacturing solutions increasingly utilize advanced technologies, such as automation and IoT integration, to enhance efficiency and precision. According to a report by MarketsandMarkets, the global aluminium processing machinery market is projected to reach $8.3 billion by 2026, growing at a CAGR of 5.3% from 2021. This statistic underscores the importance of equipping your manufacturing plant with state-of-the-art machinery that not only meets industry standards but also boosts productivity.

When selecting aluminium machinery, consider the latest innovations that can streamline operations. Machinery equipped with AI capabilities can significantly reduce operational downtime and maintenance costs. Additionally, energy-efficient machines not only lower operating costs but also contribute to sustainability goals. As an industry tip, always look for machinery that offers customizable features, allowing you to adapt to varying production needs without requiring extensive overhauls.

Investing in machines that prioritize user-friendly interfaces and remote monitoring can make a significant difference in daily operations. Operators can quickly diagnose issues and optimize performance without being physically present at the facility. This shift towards remote management represents a broader trend towards digital transformation in manufacturing, reinforcing the need for businesses to stay ahead with the right machinery and technology.